In today’s world, a growing push for renewable and low-carbon power generation has made sustainable energy sources more important than ever. For these power sources to function, durable, efficient, and reliable metals are essential. Read on to learn about the best metals for sustainable energy and power generation, what to look for, and how to choose a metal supplier to reliably source them.

What to Look For in Metals for Power Generation and Sustainable Energy

Power generation relies on exceptionally high stress environments. Metals used in these applications are exposed to corrosive chemicals, extreme temperatures, and long lifespans. Even more importantly, the stakes are high. Choosing the wrong material can result in inefficiencies, more maintenance, or premature failure. The costs can add up quickly.

Look for the following when selecting metals for power generation:

- Corrosion resistance: Sustainable power generation relies on a range of corrosive materials. Geothermal power generation involves ammonia and chlorides, offshore wind power generation occurs in corrosive marine environments, and solar power requires molten salts to generate energy.

- High temperature strength: Depending on the power source, metals used in renewable energy may reach temperatures as high as 500° C.

- Fatigue resistance: Renewable energy technologies have long lifespans. Wind turbines are designed to last for 20-25 years, while solar panels may last up to 30. Metals used in these applications must be able to withstand constant use for decades without creep or deterioration.

Best Metals for Sustainable Energy and Power

For the most efficient sustainable energy and power generation, careful metal selection is essential. Read on to learn the best power generation metals in sustainable energy sources.

Stainless Steel

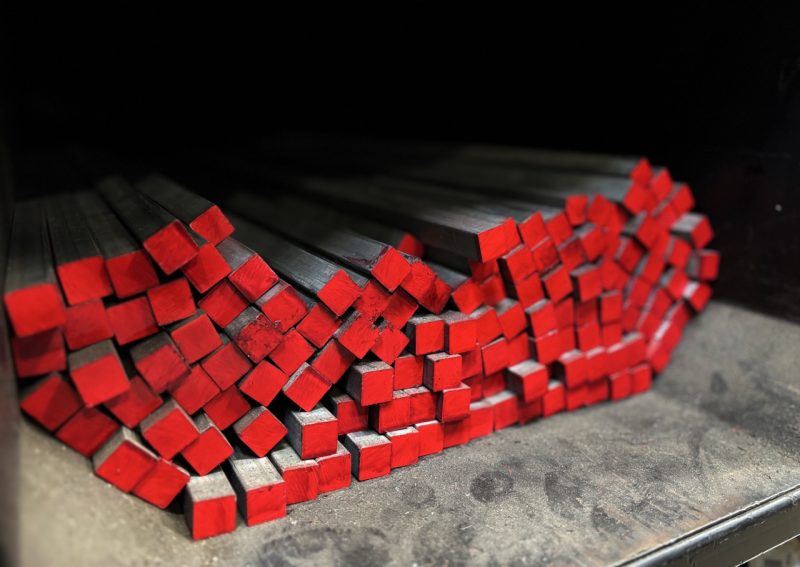

Stainless steel is the backbone of the renewable energy industry. It’s highly corrosion resistant, very strong, and fatigue resistant, making it a great choice for power generation applications. While 304 and 316 stainless steel are among the most common grades, there are several specialty grades that can be used in particularly aggressive environments.

Common sustainable energy applications for stainless steel include:

- Wind energy: Fasteners, structural components, and other parts exposed to mechanical stress, particularly in marine environments.

- Solar energy: Mounting systems, frames, and structural supports with long-term exposure to elements and temperature swings.

- Hydroelectric energy: Penstocks, gates, and turbines with direct exposure to water.

- Nuclear power generation: Piping, containment systems, and heat exchangers.

Electrical Steel

Electrical steels are critical for maximizing the energy efficiency of motors, generators, and transformers. These steels reduce energy loss, improve efficiency, and manage heat in components that convert mechanical energy into electricity.

Electrical steel metals are used in renewable energy for:

- Wind turbines: Used in generator cores.

- Power distribution systems: Used in transformers to minimize energy loss as electricity travels from generation sites to end users.

Superalloys

Superalloy metals are used in renewable energy generation to enhance strength and corrosion resistance, even at extremely high temperatures. The addition of nickel to these metals, like superalloy 718, improves their creep resistance and helps to extend their lifespan.

Common uses for superalloys in sustainable energy and power generation include:

- Concentrated solar power: Used in heat exchangers and piping systems that reach temps up to 500° C.

- Geothermal energy: Used in geothermal wells with hot, corrosive fluids.

- Nuclear power: Used in components exposed to extreme heat and radiation.

- Hydrogen production: Used for their ability to handle heat, pressure, and reactive environments without degrading.

- Thermal storage: Used in structural components in power plants.

Choosing the Right Supplier for Metals Used in Renewable Energy

When selecting energy industry metals, off-the-shelf materials simply won’t cut it. Manufacturers need access to metals with consistent chemical composition, proven performance, and reliable availability.

When choosing your metal supplier for the renewable energy industry, look for:

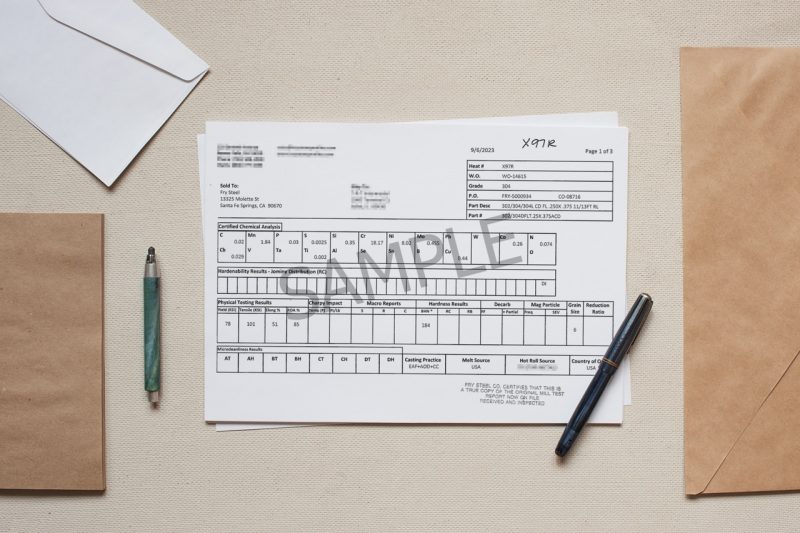

- Quality control: Seek out suppliers with strong QA processes and standard QA certifications.

- Processing capabilities: A strong metal supplier will offer processing capabilities like cut-to-size plate, bar, and more.

- Strong technical knowledge: Look for an energy industry metal supplier with the technical knowledge to guide your material selection and specifications.

Source Renewable Energy from Fry Steel

For a reliable source for the best metals for sustainable energy and power generation, partner with Fry Steel. Our in-depth metals inventory is backed by experience and processing expertise. With our help, you can move from design to deployment with confidence. To get started, find a Fry Steel rep in your region today.