In mission-critical industries like aerospace and defense, compliance is essential. At its heart is materials traceability, thorough documentation regarding the source, makeup, origin, and path of various metals. In these industries, materials traceability isn’t only a good idea, it’s a regulatory requirement.

Read on to learn all about materials traceability, why it matters, and how Fry Steel puts materials traceability at the core of our business.

What is Material Traceability?

Material traceability refers to the ability to trace a single material throughout the entire metal supply chain, from the source of its raw materials through processing to distribution. It includes information about:

- Tracking information: Traceability documentation about the source of the raw materials, their supplier, chemical composition, and mechanical properties.

- Heat number: Each batch of materials has a unique identifying number that’s used to trace it, known as a heat number. The heat number is linked to all traceability information about this material.

- Manufacturing process: Detailed information about when and how the raw materials were processed, as well as quality checks performed during its processing.

- Location information: A detailed log of the material’s location at all times, including where the materials are stored and its movement throughout the supply chain.

Why Material Traceability Matters

In high-stakes industries where small variations in materials can lead to disaster, material traceability through the metal supply chain is essential. It enhances:

- Quality control: Thanks to traceability documentation, manufacturers can ensure their materials are high quality and meet all necessary standards.

- Regulatory compliance: Many industries are held to high compliance standards. Materials traceability documentation can be used to prove metal supply chain compliance.

- Recall capabilities: In the event that a defect in the material requires a total recall, materials traceability can be used to quickly find the source of the material and all instances of its use.

Material Traceability by Industry

Depending on the industry, requirements surrounding materials traceability vary. Read on to learn the industries that require materials traceability in the metal supply chain.

Aerospace

In the aerospace industry, materials are subject to corrosion, extreme temperatures, and other sources of stress and potential failure. Each component and its materials require detailed traceability to prove compliance with rigorous standards.

Relevant QA standards that govern traceability in aerospace include:

- FAA Form 8130-3: Verifies that parts and components meet safety standards

- AS9100: Globally-recognized quality management certification that addresses materials traceability throughout the supply chain

Defense

Materials traceability throughout the metal supply chain is used to mitigate safety hazards and fraud in the defense industry. Compliance regulations in this industry include:

- DLAD Procurement Note: This document requires that vendors provide traceability information prior to supplying materials in the defense industry

- International Traffic in Arms Regulations (ITAR): Requires detailed records of all materials transactions from manufacturing to export, including information about the source, production process, quality checks, and certifications.

Energy

In the energy industry, materials traceability helps verify that materials meet quality standards and regulatory requirements. It’s also used to track the environmental and social impacts of certain materials.

Regulations in the energy industry include:

- AMSE Boiler and Pressure Vessel Code: Sets forth specific requirements for the fabrication of pressure vessels.

- Solar Supply Chain Traceability Protocol: These policies require documentation of both the source of a product’s materials and the material’s movements throughout the supply chain. It also requires an independent, third-party audit to ensure adherence to the protocols.

- GS1 Global Traceability Standard: Creates a single standard for all organizations and industries to trace end-to-end materials supply chain.

- Uyghur Forced Labor Prevention Act (UFLPA): Requires manufacturers to prove their silica-based solar panel components are not made by forced labor in the Uyghur community.

Medical Devices

For devices that support or sustain life, materials traceability throughout the metal supply chain is essential. There’s a particular focus on biocompatibility, as these devices interact with or live inside of human bodies.

Traceability requirements in the medical device industry include:

- ISO 13485: An international quality management systems standard that regulates the traceability of materials throughout the supply chain.

- FDA regulations: 21 CFR Part 80 of the FDA regulations require comprehensive traceability for all parts included in the manufacturing of a finished medical device.

Key Material Traceability Documentation

Material traceability relies on a number of key documents, including:

- Materials test report (MTR): After a document is manufactured, it’s tested to ensure its chemical composition and mechanical properties meet expected standards.

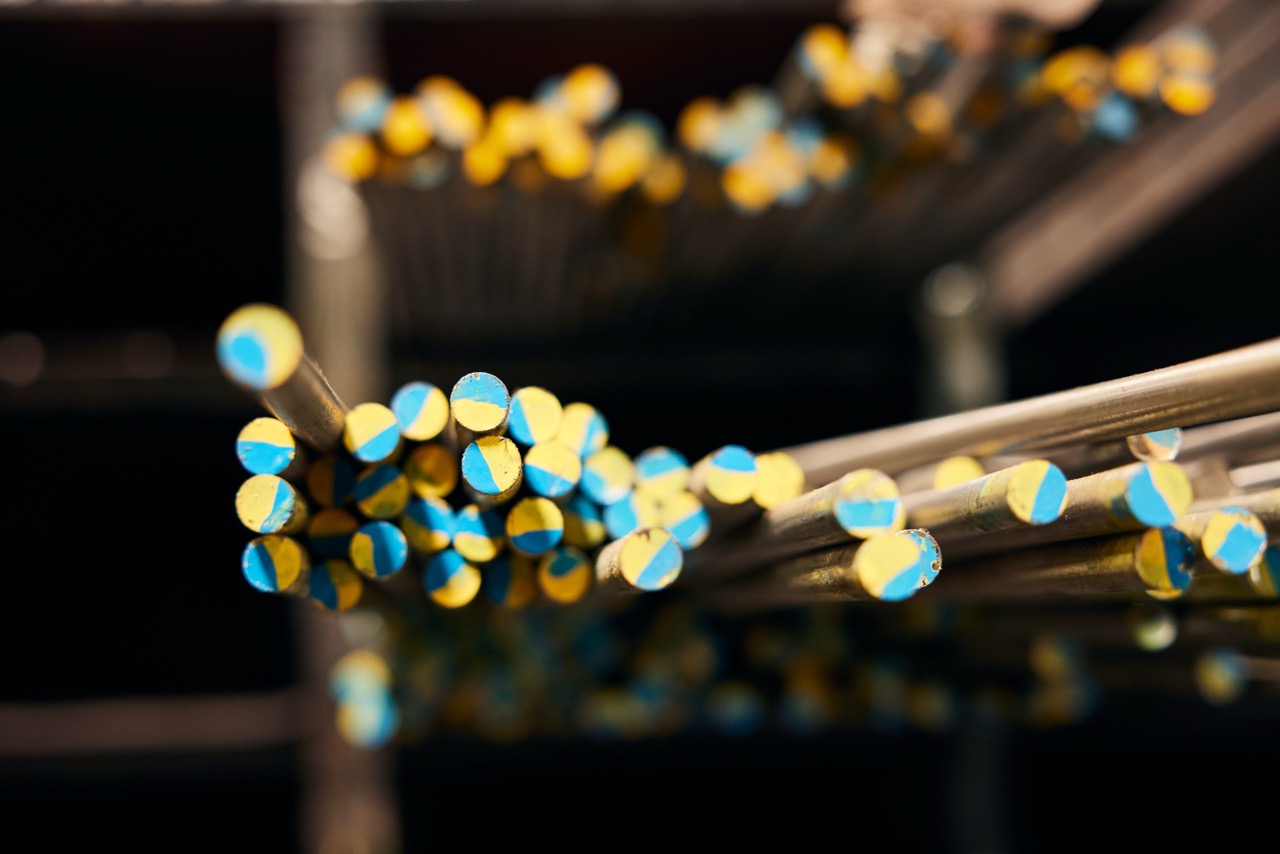

- Heat number: A material’s heat number is a unique ID number tied to each production batch. It correlates to all documentation related to that material. The heat number is printed on the material, packing slips, and more.

- Supplier documentation: Includes materials specifications and compliance certifications, like a certificate of origin and product data sheet.

What to Expect from a Supplier

When working with a materials supplier, you should expect thorough documentation with every shipment. The documentation should be clearly linked to the physical markings or tags on the materials. Your supplier should manage material traceability in a way that enables them to be ready for an audit at any time.

For added confidence, look for a supplier that holds itself to voluntary quality system standards like ISO 2001, AS9120, or other certifications relevant to their industry. These show a commitment to exceptional standards.

Fry Steel and Material Traceability

At Fry Steel, we’re committed to systems that allow easy and thorough materials traceability for your peace of mind. We’re independently ISO and AS certified, including ISO 9001, AS9120B, AS9100D, and ISO 13485. We also require our suppliers to be ISO or AS certified as well. We also act in accordance with the Supply Chain Act and ensure all of our suppliers act in accordance with the highest levels of integrity and ethical standards. When you purchase from Fry Steel, you can purchase with confidence. Contact your rep.