In industries like aerospace, defense, and medical devices, confidence in your material quality is essential. A single non-compliant material can result in safety concerns, production issues, and compliance failures.

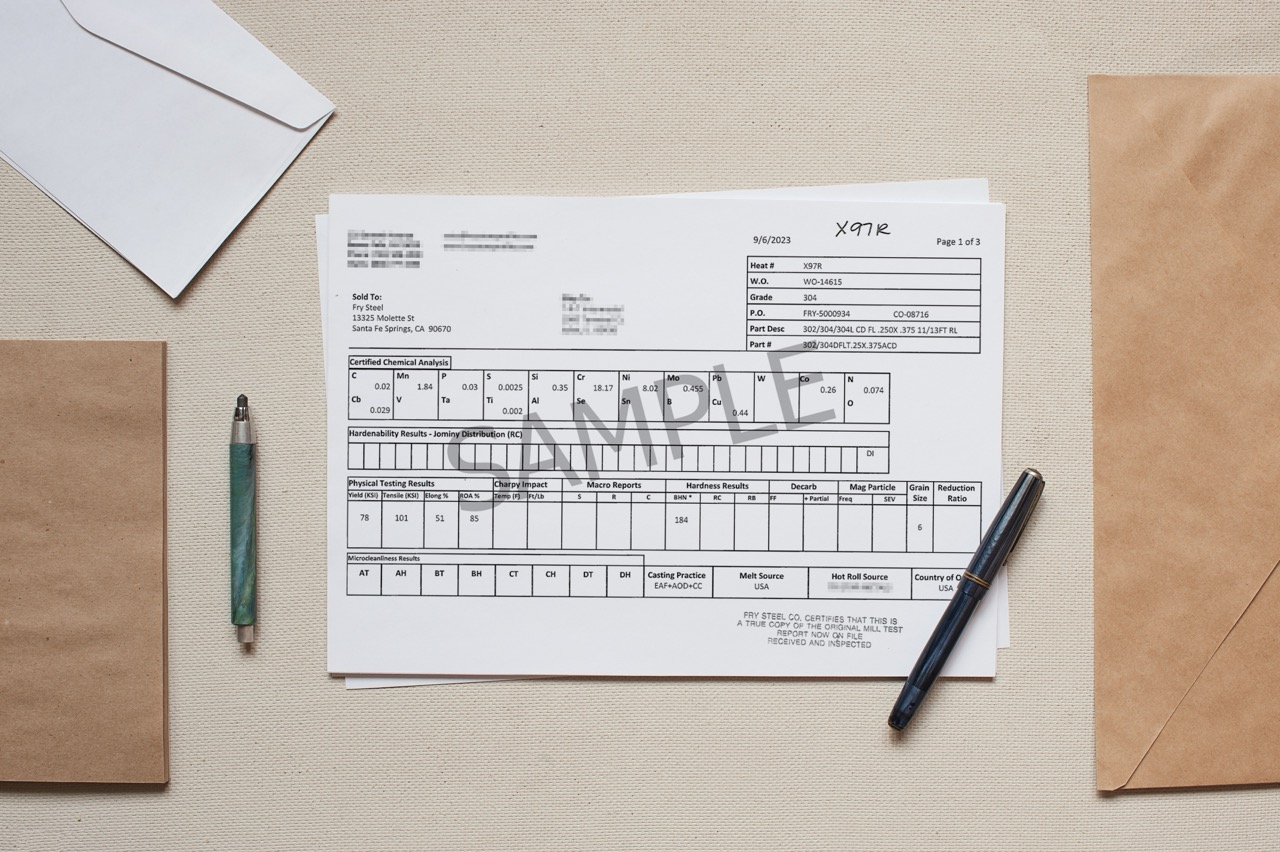

Fortunately, the industry offers a tool to verify the compliance of your materials: a material test report. This paperwork, and the tests that come along with it, verify that each material you use is exactly as expected in terms of its chemical composition, mechanical properties, and more. That’s why Fry Steel includes a verifiable, traceable material test report in every shipment and for every material.

Read on for a complete material test report breakdown, including information on how to interpret a material test report and verify its results.

What is a Materials Test Report?

A materials test report (MTR) is a type of quality assurance document that’s mandatory in the metal industry. This document is a certification of the material’s chemical and physical properties. It includes information about its chemical composition and mechanical properties, as well as information about how the material was tested. Finally, an MTR certifies the material’s compliance with industry standards.

Understanding the Structure of an MTR

Material test reports can vary based on manufacturers, product type, and more, but they all contain the same basic components. Read this material test report breakdown to understand its elements:

- Identifying information: Often at the top of the report, you’ll find identifying information, including the description of the material, including its grade, alloy, dimensions, and heat number.

- Chemical analysis: The chemical analysis shows both the required range and actual amount of each element in the material.

- Mechanical analysis: The mechanical analysis shows the required range and actual results of various mechanical tests performed on the material. This includes metrics like its hardness, impact resistance, tensile strength, and more.

- Inspection details: You’ll find information about the parties involved in the inspection, as well as whether the inspection was peer reviewed, passed QA, and more.

- Certifying signatures: These signatures certify that the information included in the report is accurate.

Verifying the Results of an MTR

Verifying your material’s compliance isn’t just a matter of reading through the MTR. It’s essential to know how to interpret a material test report to identify potential concerns.

Cross-reference heat numbers and certifications

A material’s heat number is essential to its traceability. This figure can be used to retrieve detailed records and essential information about the production of the material, including its chemical composition, manufacturing process, and quality assurance information.

Match the heat number listed in the MTR to the material’s markings and its shipping documents. Then, ensure any third-party or mill certifications align with the information related to the heat number, like the internal purchase order and job requirements. If you find any misalignment, pause and research.

Identify mechanical and chemical property benchmarks

Next, it’s time to interpret the material test report’s findings in terms of chemical and mechanical properties. Your materials test report includes both the required range and actual results for each test. If a material falls within the specified range, it’s safe to use. If not, it can’t be safely used.

Spot red flags or missing information

Thoroughly review the information on your materials test report to make sure nothing is missing. While not all materials test reports are structured in the same way, your report should include all of the above information. If any is missing, don’t use the materials.

It’s equally important to watch out for red flags when interpreting your material test report. Common red flags may include:

- Differences between test results and specifications: The information included in your materials test report breakdown should meet industry specifications, like the AMS, ASTM, ASME, and more.

- Contradictions between sections: Use your industry knowledge to identify contradictions or discrepancies between different sections of the report, like chemical compositions that don’t match up with mechanical properties.

- Significant deviations from expected results: It’s not unheard of for materials to occasionally differ from their expected results, but a pattern of consistent deviations may suggest fraud.

Understand traceability and documentation requirements

Make sure that the Materials Test Report, including physical documentation, and documentation related to your material’s heat number matches exactly. Incomplete or mismatched records can lead to compliance failures and potentially dangerous outcomes.

Once you’ve completed the MTR specification verification process, keep all documentation on-hand for the period of time required by your regulatory or QA systems. In the event of an audit, it’s important to have this information readily available.

Materials Test Reports: FAQ

Why are MTRs important in industries like aerospace, defense, and medical devices?

In high-stakes, highly-regulated industries, slight variations in materials can result in catastrophic failures. Materials test reports are used to verify the safety of a material. They ensure a material meets industry QA specifications and provide detailed traceability throughout the entire supply chain. In the event that a defect is identified or recall occurs, a manufacturer can use a material’s MTR to determine whether it’s been impacted.

How do I verify the accuracy of an MTR?

To verify the accuracy of an MTR:

- Qualify that your sources are reputable

- Cross-reference a material’s heat number to its markings, shipping documents, and mill certifications

- Ensure test results fall within required industry benchmarks

- Look for red flags or missing information

- Verify all documentation matches exactly

Can MTRs be falsified or inaccurate?

Yes, it is possible for MTRs to be both in the marketplace. Errors can occur during testing or reporting that can lead to inaccurate test results. In rare cases, MTRs can also be falsified in order to carry out fraud. To rule out either possibility, it’s essential to verify results against independent certifications and industry standards.

To protect your business from false or inaccurate MTRs, it’s essential to choose a metal supply company with a reputable history, like Fry Steel, which performs a verification process for every MTR received. Take the time to compare metal suppliers to find a partner you can trust.

Does Fry Steel provide MTRs with every order?

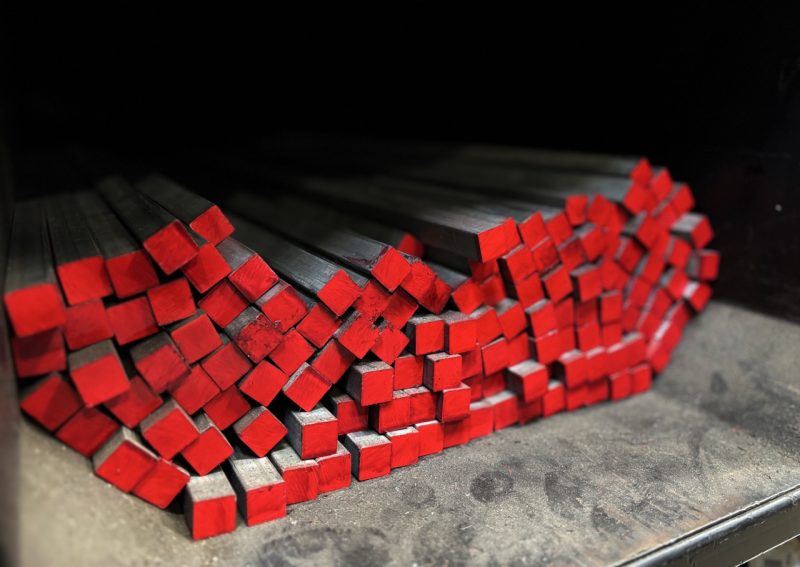

At Fry Steel, we’re committed to transparency and hold ourselves and our suppliers to rigorous standards. We include verifiable MTRs with every shipment, from aircraft alloys to exotic metals for defense, ensuring your QA and compliance teams have accurate, traceable documentation that meets industry requirements.