Modern medical devices are meticulously engineered for safety, durability, and precision. That means each medical device material used in their construction must be carefully chosen. No matter their application, metals must be extremely resistant to corrosion, have a high strength-to-weight ratio, and excellent machinability. The stakes are high; choosing the right materials may mean the difference between life and death.

Read on to learn about the best metals for medical implants, surgical equipment, and diagnostic equipment, and how to find a trusted and reliable supplier.

Titanium

Titanium, both a pure metal and chemical element, is a strong, lightweight material. It belongs in the category of transition metals, which are known for being hard, dense, and good conductors of heat and electricity.

Key Features

Titanium offers a number of key features that make it an excellent choice for use in medical devices, including medical implants, surgical equipment, and diagnostic equipment. These include:

- Exceptional biocompatibility: Titanium is generally highly compatible with the human body, even in those who are sensitive to some types of metal. It has a very low rejection rate and is unlikely to cause an immune reaction.

- High strength-to-weight ratio: Titanium is as strong as low grade steel, but about 45% lighter in weight. That results in little feeling when used implanted inside the body, and prevents fatigue during long surgical procedures.

- Excellent osseointegration: Osseointegration is the process through which bone fuses with a medical device without the need for a joint. It’s essential for medical implants like dental implants and prosthetics. Titanium creates stable, strong bonds with the body through osseointegration.

- Non-magnetic: Because titanium is a non-magnetic metal, it can be safely used in MRI machines and CT scanners.

Common Applications

Titanium is a commonly used metal in surgical instruments, medical implants, and medical diagnostic equipment. Its uses include:

- Medical implants: Joint replacements, bone screws, dental implants, and spinal implants are all commonly made from titanium.

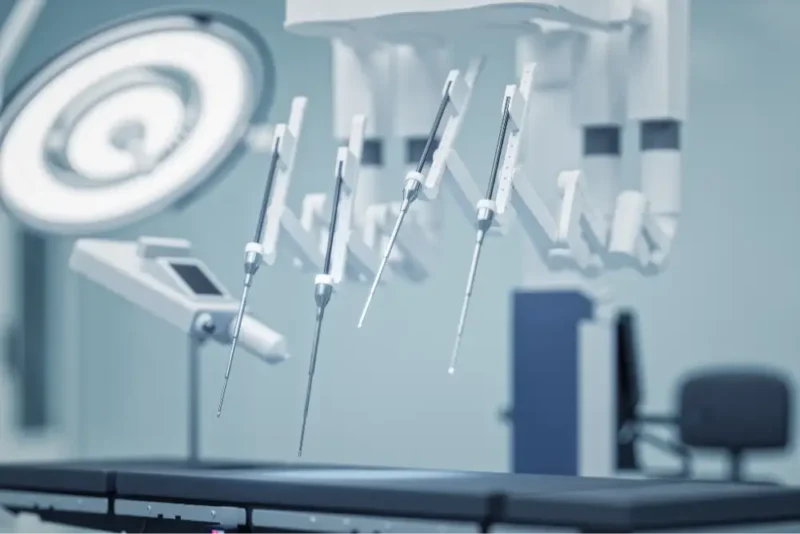

- Surgical instruments: Titanium is used to make forceps, scissors, and retractors. When used in surgery, titanium is often coated with titanium nitride to create an antibacterial surface.

- Medical diagnostic equipment: MRIs and CT scanners are often made using titanium components due to its non-magnetic properties.

Stainless Steel

Stainless steels used as medical device materials are known as medical grade stainless steel. These types of stainless steel have higher chromium and molybdenum content and lower carbon content to achieve the correct properties for medical use.

Key Features

Medical grade stainless steel presents a number of benefits that make it a great choice as a medical device material, like:

- High corrosion resistance: The chromium and molybdenum in medical grade stainless creates a protective layer of chromium oxide on the surface, which prevents rusting.

- High biocompatibility: Medical grade stainless steel is very biocompatible and has a low likelihood of triggering immune responses.

- Easy sterilization: Because medical grade stainless steel is smooth and non-porous, it can be easily and safely sterilized over and over again.

- Low cost: Stainless steel tends to be a less expensive metal, making it a more affordable choice than other more costly materials.

- Sharp edges: Particularly important for surgical instrument materials, stainless steel can be used to create an extremely sharp edge.

Common Applications

Medical grade stainless steel is used to make medical implants, surgical equipment, and medical diagnostic equipment. It can be found in:

- Medical implants: Medical grade stainless steel is used to make temporary implants like plates, screws, and pins. It’s also commonly used in artificial heart valves and stents.

- Surgical instruments: This type of stainless steel is a common metal for surgical equipment like scalpels, forceps, and cutting tools.

- Diagnostic equipment: Austenitic stainless steel, which is non-magnetic, can be found in the external structure of diagnostic machines like MRI machines. Other types can be used in the housing of glucose meters, blood analyzers, and more.

What to Look For in a Medical Device Materials Supplier

As important as choosing the right medical implant, diagnostic equipment, and surgical instrument materials is choosing a reliable and trustworthy supplier. Look for the following when selecting your medical device supplier:

- Certification for medical devices: Look for a materials supplier who is certified in quality management system standards for medical devices, like ISO 13485. This certification ensures that your supplier holds themself to rigorous safety and compliance standards.

- Processing capabilities: In addition to supplying your materials, look for a supplier with processing capabilities, like custom cutting, and grinding. Ensure your supplier can meet the tight tolerances required by the medical industry.

- Reliable service: Reliability, fast delivery, and responsive customer service are essential when meeting tight timelines.

- Industry expertise: Your medical device materials supplier should have the knowledge and expertise to match your device requirements with specific material grades in their inventory.

Fry Steel: Medical OEMs’ Trusted Supplier

Selecting the right materials supplier directly impacts the safety, performance, and longevity of your medical devices and equipment. For a dependable partner with specialty materials, trusted quality, and exceptional processing capabilities, trust Fry Steel. With decades of experience in the metals industry, we provide solutions to support businesses across the medical industry.

Ready to get started? Contact us to find a Fry Steel representative today.