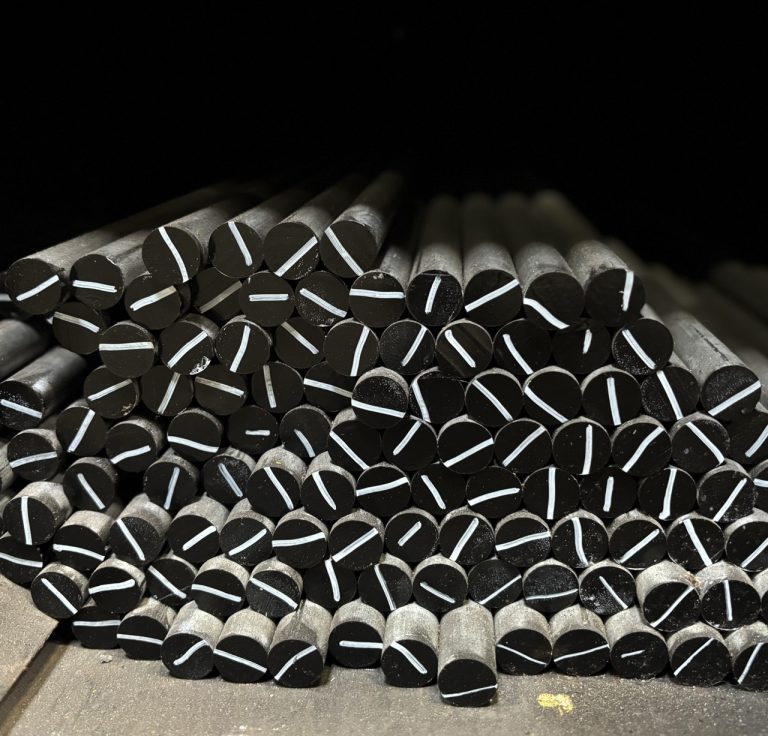

Engineered for structural applications, boats, aircraft components and engineering. Available in multiple shapes & sizes.

6061 aluminum is a versatile, heat-treatable alloy known for its excellent strength, corrosion resistance, and machinability. Containing magnesium and silicon as its primary alloying elements, 6061 offers a strong balance of mechanical properties and weldability, making it one of the most widely used aluminum alloys. Common applications include aerospace components, automotive parts, structural materials, and marine equipment, where lightweight durability and reliability are essential.

Explore all Aluminum Products | View Certifications

| Element | Min | Max |

|---|---|---|

| Silicon, Si | 0.4 | 0.8 |

| Iron, Fe | - | 0.7 |

| Copper, Cu | 0.15 | 0.4 |

| Magnesium, Mg | 0.8 | 1.2 |

| Manganese, Mn | - | 0.15 |

| Chromium, Cr | 0.04 | 0.35 |

| Zinc, Zn | - | 0.25 |

| Titanium, Ti | -- | 0.15 |

There are 18 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are 4 sizes and conditions.

There are 4 sizes and conditions.

There are 60 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are 12 sizes and conditions.

There are 18 sizes and conditions.

There are 84 sizes and conditions.

There are 187 sizes and conditions.

There are 24 sizes and conditions.

There are 17 sizes and conditions.

There are 4 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

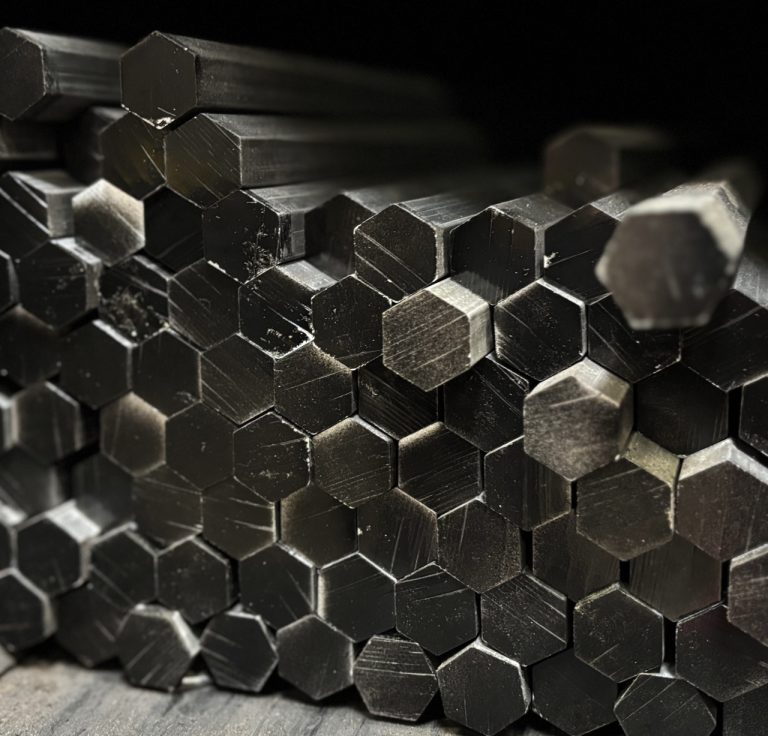

There are no sizes and conditions for the hex cross-section.

Fry Steel has an ISO 9001 certification specific to aerospace SAE standards AS9100D & AS9120B, so we meet the global industry quality standard. Our suppliers are held to the same standard, and the stock is traceable. We’re audited every year by International Standards Authority, Inc. to ensure our quality program meets all current requirements.

What stands out most is the extremely quick service and amazing people. From cutting the PO to matching it with invoices, it’s just an incredibly smooth process. I have had 0 issues with order discrepancies in that regard. The people that work at Fry are absolutely amazing and SO incredibly kind and hardworking.

Fry Steel Company is a leading raw material supplier globally. Fry Steel’s ISO 9001/AS9120/AS9100D certification is your assurance that we meet the global industry standard for quality. We hold our suppliers to the same standard, so all of our metal stock is completely traceable. Our ISO 9001/AS9120/AS9100D program is audited annually by International Standards Authority, Inc.

Next day shipping is available on in-stock, qualifying orders. Fulfillment times vary for material that requires ordering from a vendor. Reach out to you rep for more information.

Yes. 6061 aluminum is bendable and can be formed using standard metalworking techniques. While it’s not as soft as some other aluminum alloys, it responds well to bending, rolling, and shaping when in the correct temper.