Date Published: February 8, 2025 | Date Modified: December 8, 2025

Metal is a versatile and durable material that is used in many of the things we rely on every day. Read on to learn about the five most common metals, their key properties, and how they are used across vital industries. Then, discover how to select the best metal supplier for your needs.

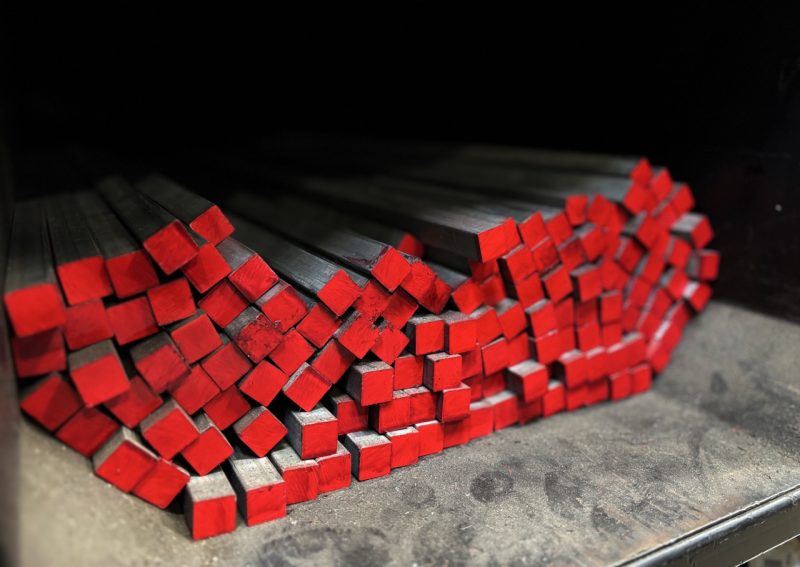

Steel

Steel is one of the most common types of metal used today. Carbon steel is a combination of iron and carbon, while steel alloys contain other elements, like magnesium, chromium, nickel, or molybdenum.

Key Properties of Steel

Steel is known for its strength and toughness. Depending on its composition, steel has additional properties like:

- Corrosion resistance: Adding molybdenum and chromium to steel increases its corrosion resistance.

- Ductility: Due to its low carbon content, low carbon steel is very ductile and has high machinability.

- Hardness: High-carbon alloy steel contains high levels of carbon in addition to tungsten and cobalt, which increase its hardness.

- Magnetic: Ferritic steel, which has a high chromium content and low carbon content, is magnetic.

Common Industrial Uses of Steel

Steel is an incredibly practical type of metal used today. Its versatility and durability make it an ideal choice for critical components, making it one of the most common types of metal in the world. It can be found in the following industries:

- Manufacturing: Steel is used to create industrial machinery parts, cutting and shaping tools, and bolts and fasteners.

- Aerospace: Steel alloys are commonly found in fuselages, landing gear, engine parts, and aircraft fasteners.

- Medical: Medical grade stainless steel is used in surgical tools, implants, and medical devices.

- Energy: Pipelines, transformers, and wind turbine towers are made of steel. It’s also used to reinforce cables.

Aluminum

Aluminum is a lightweight metal that’s extracted from bauxite ore using an electrical process known as electrolysis. While extraction is a highly energy-intensive process, aluminum can be easily recycled, which uses only 5% of the energy of extraction.

Key Properties of Aluminium

Aluminium is known for its light weight, strength, and durability. Depending on the particular aluminum alloy, its properties include:

- Conductivity: Pure aluminium is very electrically and thermally conductive.

- Strength: When alloyed with zinc, copper, or magnesium, aluminium exhibits high strength.

- Ductility: Silicon-aluminium alloys are highly ductile.

- Formability: Aluminium-manganese alloys exhibit good formability.

Common Industrial Uses of Aluminium

Aluminium’s lightweight and corrosion-resistant properties make it ideal for applications where weight and durability are important factors:

- Manufacturing: Aluminium is often found in car parts like engines and chassis. Long bar aluminum is used to create components such as beams, frames, and structural supports.

- Aerospace: Aircraft airframes are primarily made of aluminium, as are spacecrafts, satellites, and space shuttles.

- Medical: Aluminium’s non-porous surface makes it a common choice for surgical instruments and medical equipment.

- Energy: Due to its high conductivity, aluminium is often utilized in powerlines and electrical components.

Zinc

Zinc is extracted from ore and refined through a process known as smelting. It can be cast on its own or alloyed with other metals for a variety of applications.

Key Properties of Zinc

Whether on its own or alloyed, zinc’s properties make it one of the most common types of metal used today. They include:

- Corrosion resistance: Pure zinc is often added to other metals to enhance their corrosion-resistance. It is often used as a coating on steel and iron to prevent corrosion.

- Castability: Zamak alloys (zinc, magnesium, aluminium, and copper) have high fluidity and low melting point, making them excellent for casting.

- Strength: When used in zinc-aluminium alloys, zinc can be strong and hard.

- Machinability: Zinc-led alloys are used for their excellent machinability.

Common Industrial Uses of Zinc

Zinc’s ability to enhance the corrosion resistance of other metals make it a common choice across a range of industry:

- Manufacturing: Zinc is used to die-cast precise parts, as well as to coat steel and iron parts like nuts, bolts, and screws.

- Aerospace: Zinc is used to coat fasteners and engine parts to prevent corrosion.

- Medical: Medical devices are coated in zinc to provide antimicrobial protection. Die-cast zinc alloys are also used to make blood pressure monitors, respiratory devices, and more.

- Energy: Zinc is one of the most common types of metal in certain batteries.

Bronze

Bronze is an alloy of copper and tin. It’s been one of the most common types of metal since ancient times, when it was used to make tools, weapons, and armor.

Key Properties of Bronze

Bronze’s long history is largely due to its range of beneficial properties, whether used on its own or with the addition of other materials. They include:

- High strength: When combined with aluminium or phosphorus, bronze is very hard and strong, with good wear resistance.

- Durability: Bronze tends to be an extremely durable metal, making it a good choice for load-bearing uses.

- Corrosion resistance: Tin lends bronze strong corrosion resistance.

Common Industrial Uses of Bronze

Bronze’s strength and durability make it a common metal type across a range of industries like:

- Manufacturing: Due to its corrosion resistance, bronze is commonly found in water and chemical pumps. It’s also used in bearings and gears.

- Aerospace: Bronze is used in landing gear, pistons, rotators, and other applications that require strength and durability.

- Medical: Because bronze is malleable, it’s used to create intricate medical devices.

- Energy: Bronze can be found in turbine components and power plants.

Iron

Iron is another very common type of metal used today. It’s known for its strength and durability. While it can be used on its own, today it’s most commonly used in its alloy form, like steel. automotive and machinery parts, tool and die making, construction equipment, agricultural machinery, and hardware manufacturing. It is also frequently used in the production of small components for the medical and aerospace industries.

Source Your Metal From Fry Steel

In addition to choosing the right type of metal for your application, it’s essential to source your metal from a reliable and trustworthy metal supplier like Fry Steel. Our extensive inventory and meticulous quality assurance practices ensure you get the highest quality product when you need it. With over 75 years in the metal supply industry, we have the expertise and knowledge to help you find the best metal for the job. Contact us today to get started.