Heat treating has historically been viewed as a necessary but mundane step in the manufacturing process. Parts were created, heat treated, and expected to come back close enough to spec to function. But in today’s increasingly demanding landscape, that approach is no longer enough. As performance expectations increase, heat treating is getting more attention than ever.

Read on to learn all about the future of heat treating, including the factors impacting it and what to expect as we move into 2026.

Driving Factors Impacting the Heat Treating Landscape

Approaches to heat treating are shifting across key industries, from industrial and automotive to aerospace, defense, and more. Read on to learn about the driving factors influencing these changes.

Evolving Performance Expectations

Today, parts are expected to be stronger, lighter, and longer-lasting than ever before. As technologies advance, components must perform under extremely high loads, rapid speeds, and extreme conditions. Heat treating, which affects hardness, strength, and toughness, is the primary tool used to meet these requirements.

As performance expectations increase, generic heat treating specifications no longer meet manufacturers’ needs. Instead, heat treating techniques must be precisely matched to the material and the final part.

Tighter Tolerances and More Precise Manufacturing

Advances in machining have led to tighter tolerances and more complex part configuration. This need for greater precision results in smaller margins of error for heat treating. As margins of errors shrink, cost increases.

Greater Need for Reliability

Another significant factor impacting the future of heat treating is the increasingly high cost of error. Subpar heat treating or poor matches in materials and process can lead to downtime, safety risks, and more. Precise and effective heat treating plays a significant role in preventing part failure and protecting manufacturers.

Future of Heat Treating: What to Expect

Looking forward into 2026, heat treating trends will continue towards greater control, improved consistency, and new technologies that support better outcomes.

Greater Process Control

Precision metal manufacturers like Fry Steel are achieving better heat treatment outcomes through the use of more advanced equipment, better temperature control, and more precise monitoring tools. These technologies allow for outcomes that more closely align with expectations. As the industry continues to trend towards more complex parts operating in higher stress environments, process control is only expected to increase.

Improved Consistency and Reliability

Manufacturers’ expectations are also predicted to increase as we move through 2026. Greater demand for consistency from batch to batch requires a combination of more precise heat treating processes and higher quality steel. As each of these factors improves, heat treating is expected to become easier and more reliable over time.

Emerging Heat Treating Trends and Technologies

Heat treating technology is evolving to meet these rising expectations. New technologies like more advanced furnace controls and sensors, deep data analytics, and the introduction of AI into heat treating processes are helping manufacturers achieve better results. With their help, heat treaters can meet tighter tolerances, reduce variability, and improve performance. They also improve documentation, traceability, and quality assurance.

The Role of Suppliers in Heat Treating Outcomes

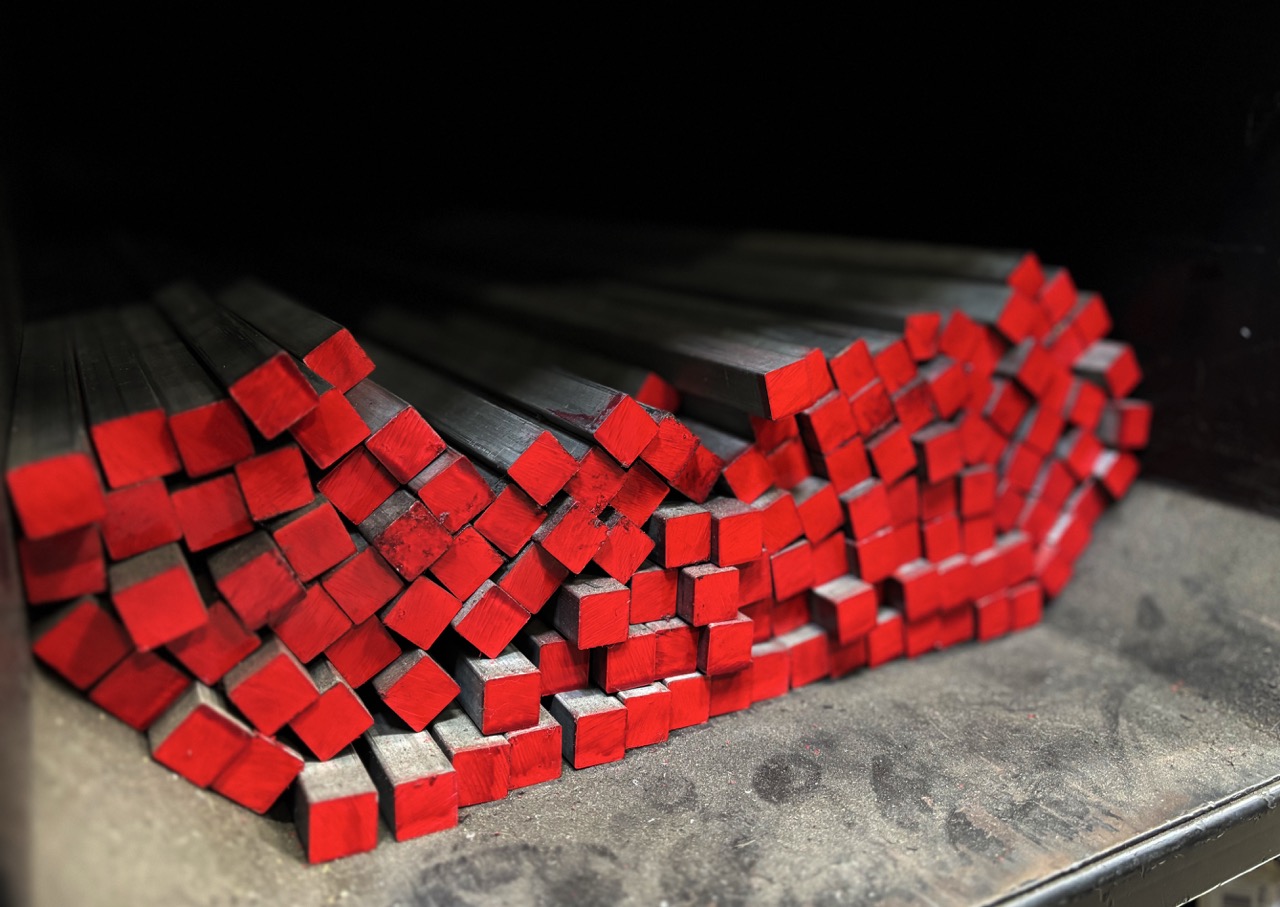

Advancements in heat treating technologies are only one piece of the puzzle. The other large piece is steel quality. The chemical makeup, purity, and structure of steel all affect how it responds to heat treating.

To match evolving heat treating technologies with the best materials, it’s essential to partner with an experienced and certified supplier like Fry Steel. They can help guide you towards materials that align with goals and expected outcomes for more predictable heat treating results. The experienced precision metal suppliers at Fry Steel have the advanced knowledge and deep inventory required to achieve the outcomes you need.

Prepare for the Future of Heat Treating With Fry Steel

As heat treating continues to evolve, it is becoming an essential part of the manufacturing process, rather than a last step. By partnering with the right supplier and selecting the best materials, you can continue to create parts that meet your precise needs. Discover Fry Steel’s services today.