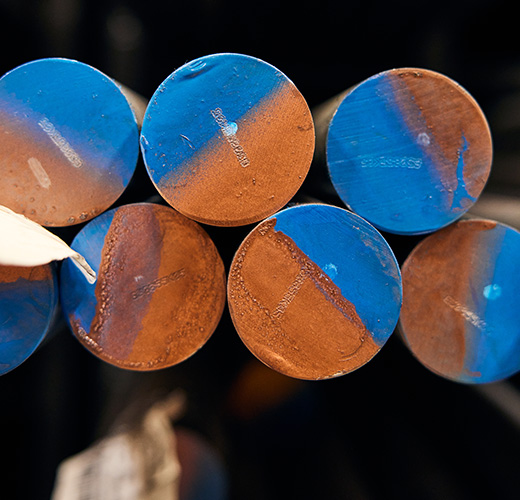

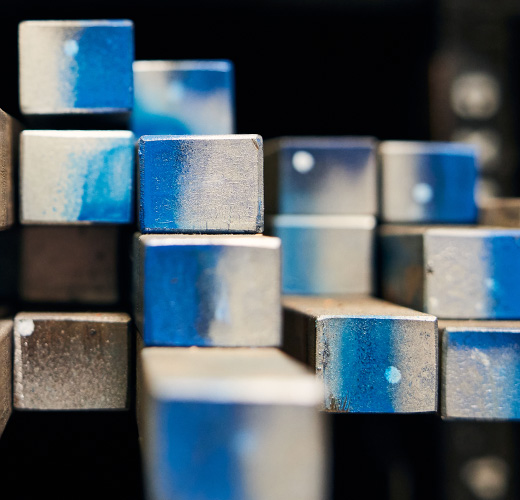

Engineered for aerospace, automotive and industrial applications. Available in round, flat, square and hex.

Incoloy A-286 (UNS S66286) is an iron-based superalloy known for its high tensile strength and excellent resistance to corrosion and oxidation, even at elevated temperatures. A-286 is a superalloy, but still classified as stainless steel since it’s iron-based with at least 10.5% chromium. Commonly used in aerospace and industrial gas turbine applications, A-286 offers reliable performance in extreme environments.

Explore all Super Alloys | View Certifications

| Element | Min | Max |

|---|---|---|

| Carbon, C | - | 0.08 |

| Manganese, Mn | - | 2 |

| Silicon, Si | - | 1 |

| Phosphorus, P | - | 0.025 |

| Sulfur, S | - | 0.025 |

| Chromium, Cr | 13.5 | 16 |

| Nickel, Ni | 24 | 27 |

| Molybdenum, Mo | 1 | 1.5 |

| Titanium, Ti | 1.9 | 2.35 |

| Boron, B | 0.003 | 0.01 |

| Vanadium, V | 0.1 | 0.5 |

| Cobalt, Co | - | 1 |

| Aluminum, Al | - | 0.35 |

| Copper, Cu | -- | 0.5 |

Must Heat Treat for capable of 160 KSI.

There are 24 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

There are 10 sizes and conditions.

Must Heat Treat for capable of 210 KSI

There are 35 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

There are no sizes and conditions for the hex cross-section.

Heat Treated to “as shipped” Min Tensile of 140 KSI.

There are 81 sizes and conditions.

There are 13 sizes and conditions.

There are 9 sizes and conditions.

There are 19 sizes and conditions.

Heat Treated to “as shipped” Min Tensile of 130 KSI

There are 44 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

There are 10 sizes and conditions.

There are 34 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

There are no sizes and conditions for the hex cross-section.

Fry Steel has an ISO 9001 certification specific to aerospace SAE standards AS9100D & AS9120B, so we meet the global industry quality standard. Our suppliers are held to the same standard, and the stock is traceable. We’re audited every year by International Standards Authority, Inc. to ensure our quality program meets all current requirements.

Their customer service is great! I know that when I email Stephanie for a quote I am going to get a quick response. The prices at Fry Steel are competitive and reasonable. I also know that if I am having an issue getting material that is not common they are most likely going to have it. They are great at answering any questions I have.

Fry Steel Company is a leading raw material supplier globally. Fry Steel’s ISO 9001/AS9120/AS9100D certification is your assurance that we meet the global industry standard for quality. We hold our suppliers to the same standard, so all of our metal stock is completely traceable. Our ISO 13485/9001/AS9120/AS9100 program is audited annually by accredited third parties.

Next day shipping is available on in-stock, qualifying orders. Fulfillment times vary for material that requires ordering from a vendor. Reach out to your rep for more information.

A-286 is both a stainless steel and a superalloy. If someone says stainless steel A-286, they’re emphasizing its corrosion resistance and stainless-like properties. If they say superalloy A-286, they’re highlighting its high-temperature strength and use in aerospace, gas turbines, and high-performance fasteners. In short: A-286 is both a stainless steel and a superalloy — an iron-based superalloy that also belongs to the stainless family.

A-286 is similar to certain austenitic stainless steels, particularly Type 310 stainless steel, in terms of its forging, formability, and machinability properties. It’s also comparable to 316/316L stainless steel in terms of aqueous corrosion resistance. Furthermore, A-286 is often compared to Inconel 718 in the context of jet engine applications, where it’s known for its high strength at elevated temperatures.