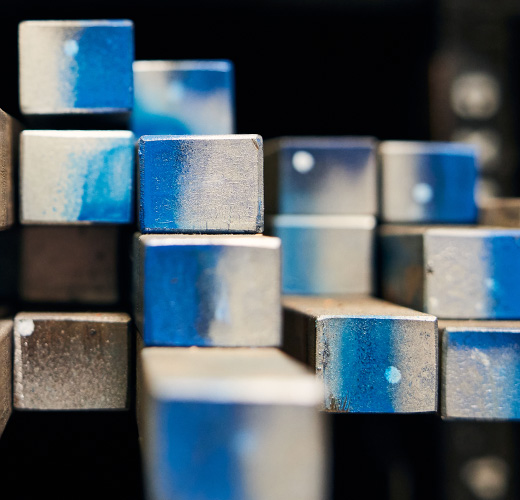

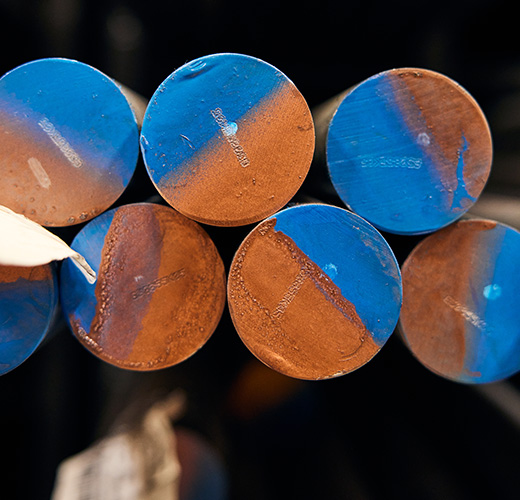

440 stainless delivers exceptional strength, hardness, and durability — ideal for demanding applications. Stocked in a variety of shapes and sizes.

440 Stainless Steel is a high-carbon, martensitic stainless alloy engineered for excellent hardness, wear resistance, and durability. When properly heat-treated, 440 can reach up to ~58 HRC and higher, giving it superior strength and edge retention while still delivering moderate corrosion resistance. Commonly used for precision components, tooling, hardware, bearings, and structural or industrial parts that demand toughness and long-lasting performance.

Explore all Stainless Products | View Certifications

High hardness and wear resistance

Strong and durable under load

Good machinability (in annealed condition) and formable into various shapes

Available in multiple sizes and tempers

| Element | Min | Max |

|---|---|---|

| Carbon, C | 0.6 | 0.75 |

| Manganese, Mn | - | 1 |

| Silicon, Si | - | 1 |

| Sulfur, S | - | 0.03 |

| Phosphorus, P | – | 0.04 |

| Chromium, Cr | 16 | 18 |

| Nickel, Ni | - | 0.75 |

| Molybdenum, Mo | - | 0.75 |

| Copper, Cu | - | 0.5 |

There are 31 sizes and conditions.

There are 1 sizes and conditions.

There are no sizes and conditions for the square cross-section.

There are no sizes and conditions for the hex cross-section.

There are 117 sizes and conditions.

There are 107 sizes and conditions.

There are 12 sizes and conditions.

There are 4 sizes and conditions.

There are 30 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

There are no sizes and conditions for the hex cross-section.

There are 36 sizes and conditions.

There are no sizes and conditions for the flat cross-section.

There are no sizes and conditions for the square cross-section.

There are no sizes and conditions for the hex cross-section.

Fry Steel has an ISO 9001 certification specific to aerospace SAE standards AS9100D & AS9120B, so we meet the global industry quality standard. Our suppliers are held to the same standard, and the stock is traceable. We’re audited every year by International Standards Authority, Inc. to ensure our quality program meets all current requirements.

Fry Steel has always gone above and beyond for me and my team. Even ever I have a technical question Fry Steel’s Sales team does an amazing job at explaining and educating me on all of my material requirements. The products Fry steel offers are one of the best in all of the metal industry and the material is always delivered in a timely manner. The drivers are very nice and experienced!!

Fry Steel Company is a leading raw material supplier globally. Fry Steel’s ISO 13485/9001/AS9120/AS9100D certification is your assurance that we meet the global industry standard for quality. We hold our suppliers to the same standard, so all of our metal stock is completely traceable. Our ISO 13485/9001/AS9120/AS9100D program is audited annually by International Standards Authority, Inc.

Next day shipping is available on in-stock, qualifying orders. Fulfillment times vary for material that requires ordering from a vendor. Reach out to you rep for more information.

440C offers good corrosion resistance for a high-carbon stainless, but it’s not as corrosion resistant as 304 or 17-4.

Because 440C has a high carbon content for hardness, it can be more prone to staining or pitting—especially in chlorides, moisture, or saltwater environments. It’s chosen for its wear resistance and hardness, not top-tier corrosion resistance.

Yes—440C can be challenging to machine, especially in the hardened condition.

Most shops prefer 440F for machining and 440C for maximum wear resistance and hardness.