Build and Bring Your Ideas to Life.

Fry Steel empowers the world to source the raw materials to make projects happen.

Fry Steel empowers the world to source the raw materials to make projects happen.

Industries

Providing the raw materials that lead to advancements in industries worldwide.

Our high-quality materials deliver stronger performance at higher temperatures, reduce weight, and help decrease fuel consumption.

View Space

From supply reliability to providing trusted advice, our materials are reliable, and cost-effective through superior performance.

View Commercial Aerospace

We provide advanced specialty materials for life and flight-critical applications. On a performance level, the result is lighter components, increased operating hours, and reduced field failures.

View Defense

Our high-quality materials deliver stronger performance at higher temperatures, reduce weight, and help decrease fuel consumption.

View Naval

Specialty alloys are ideally suited for a wide variety of flow control, continuous flow, and material processing applications.

View Industrial

Our metals are specifically designed to operate at the highest levels of performance and reliability, even in harsh environments, high temperatures, and extreme operating stresses.

View Power Generation

Literally from the inside out, we work closely with the medical industry as a metal supplier to provide solutions that support the smallest of implants to medical devices across healthcare.

View Medical

With over 10,000 items, our drops and remnants are created from in-house processing orders. Our remnant inventory includes high-quality products at a discounted price.

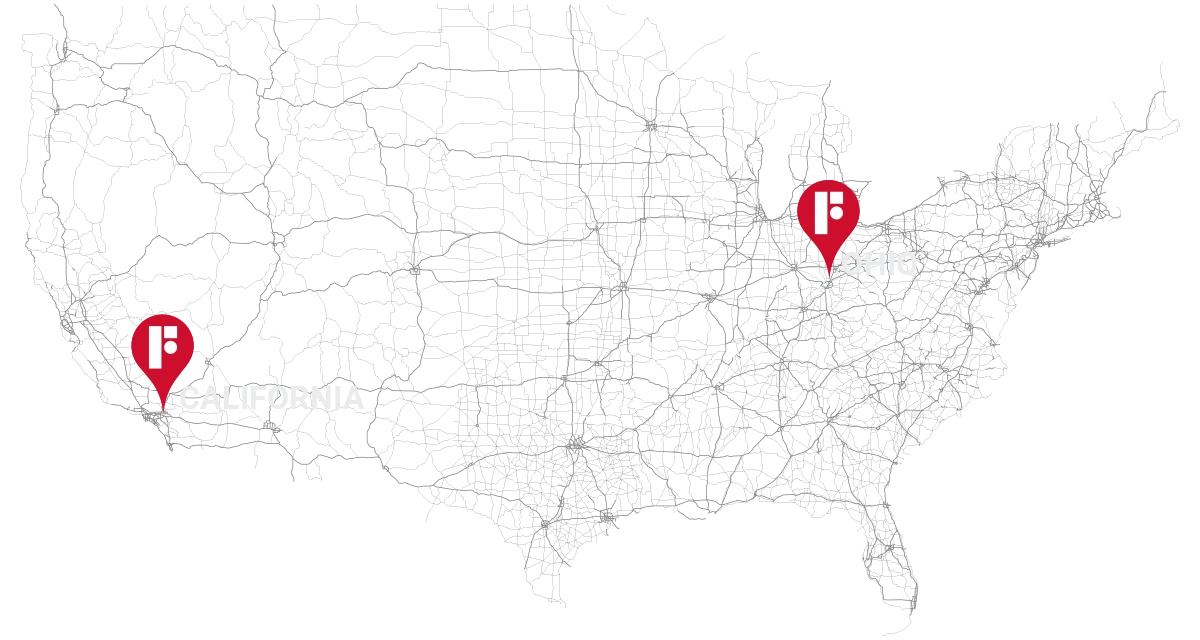

13325 Molette St.

Santa Fe Springs, CA 90670

From California to Ohio and beyond—Fry Steel has got you covered. With several tight-tolerance saws, expanded inventory offering, and decades of industry know-how, Fry Steel is uniquely positioned to service all your long bar metal needs nationwide.