Getting started in the precision metal industry can be a challenge. First-time buyers are often faced with confusing specs, unfamiliar terminology, and inconsistent supplier quality, leading to frustration, wasted time, and sunk cost. Fortunately, with a few fundamentals, anyone can confidently source the precision metals they need to get the job done.

This precision metals guide contains all the information you need to get started, including how to select materials and grades, information about size, shape, and tolerance, and guidance on selecting the best precision metal supplier.

Selecting the Best Material For Your Application

The first step in sourcing precision metals is the most basic: selecting your metal type. Read on to learn how to narrow your selection down to a specific metal.

Precision Metal Properties

Each metal has a specific set of properties that may be advantageous in the construction of your part. Consider the following properties to help guide your decision:

- Strength: Think about how much weight your part needs to support. You may be creating a load-bearing part, a purely cosmetic part, or anywhere in between.

- Weight: In some cases, you may need a metal with a high strength-to-weight ratio, meaning it can support a significant amount of weight while remaining light.

- Corrosion resistance: Consider the environment your part will be in. If it has exposure to chemicals or moisture, you may need to source a precision metal with high corrosion resistance.

- Machinability: Does your part require tight tolerances? If so, finding a metal with good machinability is key.

- Fatigue resistance: For parts that are repeatedly subject to stress, like rotation, vibration, high weight bearing, and more, it’s vital to choose a metal with good fatigue resistance.

- Porosity: If sterilization is a consideration, a non-porous material is important.

Pairing Metals With Properties

Once you’ve identified the properties you require, it’s time to choose a metal that has them. Use the following chart to identify the best precision metal for your needs.

| Property | Material Options |

| High strength | Tungsten, titanium alloys, steel alloys |

| High strength-to-weight ratio | Titanium, titanium alloys |

| Strong corrosion resistance | Stainless steel, titanium, nickel alloys |

| Good machinability | Stainless steel, aluminium, carbon steel |

| High fatigue resistance | Titanium alloys, nickel alloys |

| Non-porous | Stainless steel, aluminium, titanium, nickel alloys |

Choosing the Right Material Grade

Once you’ve narrowed it down to the best material, the next step in the precision metals guide is to select your material grade.

What is Metal Grade

Precision metal grade is a classification method that’s used to identify specific types of metals. Each grade has a slightly different chemical composition that influences the metal’s properties. For instance, under the umbrella of stainless steel, you’ll find these common grades:

- Stainless steel 316: Contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum makes it highly resistant to corrosion, but more expensive.

- Stainless steel 304: Contains 18-20% chromium and 8-10.5% nickel. It’s less corrosion resistant, but more cost-effective.

- Stainless steel 420: Contains at least 12% chromium and 0.15-0.40% carbon. The addition of carbon makes it a very strong and hard stainless steel.

Most Popular Metal Grades

Find the most common grades for popular precision metals below:

- Titanium and titanium alloys: Titanium 2 has high strength and weldability, titanium 5 has high corrosion and heat resistance, titanium 1 has the best machinability.

- Steel and steel alloys: In addition to the most common stainless steels, choose 52100 alloy steel for fatigue resistance and 4340 alloy steel for strength and hardness.

- Aluminium: 1100 aluminium has high corrosion resistance and conductivity, 3003 aluminium has excellent corrosion resistance and good strength, 7075 aluminium has exceptional strength-to-weight ratio.

Understanding Tolerances, Sizes, and Shapes

The next step in finding the right precision metal is determining tolerance, size, and shape:

- Tolerance: In machining, it’s nearly impossible to create a part to precise specifications every time. Tolerance is the acceptable range of variation in a part’s dimensions in which a part will still function correctly. The smaller the tolerance, the more expensive the part, so it’s important to balance precision with cost.

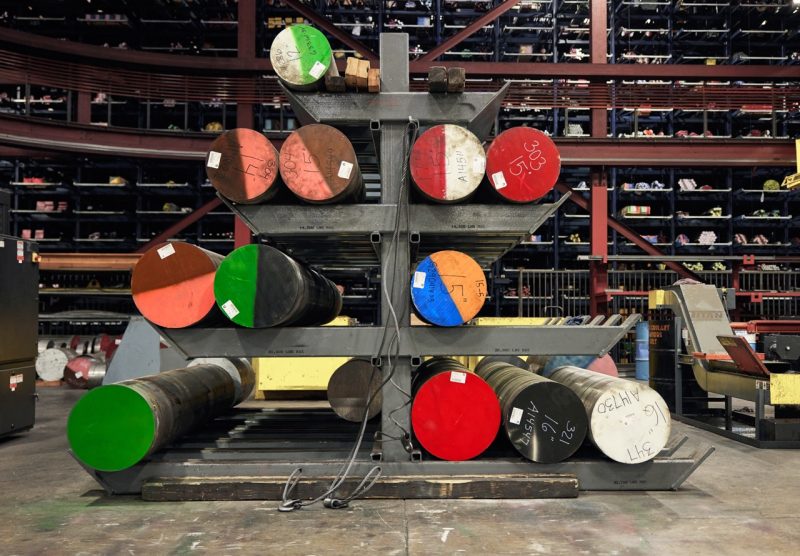

- Size and shape: In addition to tolerance, it’s important to consider size and shape. Precision metals can be manufactured in bars, sheets, tubes, plates, and more. While most metals can be machined after purchase into their desired size and shape, buying closest to your desired finish size is typically cheapest.

- Surface finish: Lastly, decide surface finish. In addition to cosmetics, different surface finishes can improve wear and corrosion resistance, durability, conductivity, and more. Finishing may be done via mechanical, chemical, or electrical processes.

Selecting a Supplier

Lastly, it’s time to select your precision metal supplier. Signs of a good precision metal supplier include:

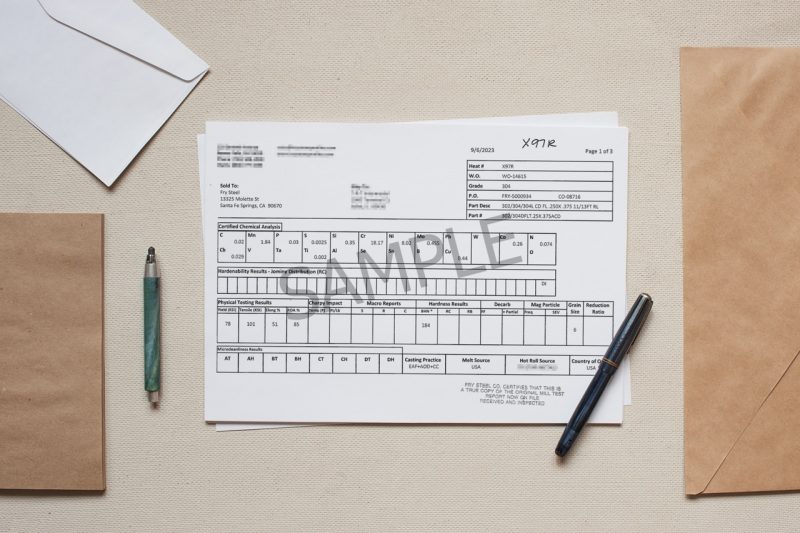

- Mill test reports: These QA documents certify that each material has the correct composition, properties, dimension, and more. Your supplier should be able to provide these upon request.

- Lot traceability: Each lot of metal should be able to be traced along its entire journey throughout the supply chain.

- Certifications: ISO certifications verify that your supplier uses a QMS system that meets the requirements set forth by the International Organization for Standardization. Your supplier should hold an ISO certification that’s specific to your industry.

- Reliability: Precision metal supplier partnerships need to be reliable, both in terms of materials supply and customer service.

- Value-add services: Look for a supplier with value-add services, like cutting, inventory management, and next-day metal delivery services.

Source Precision Metals With Confidence From Fry Steel

For a trustworthy precision metal supplier that offers reliability and expertise, partner with Fry Steel. We bring more than 75 years’ experience in metal supply. With specialization in a range of industries, including space, defense, naval, industrial, and more, we possess the knowledge and inventory you need to be successful. Contact us today to get started.