Selecting the right metal supplier isn’t just a purchasing decision. It’s a partnership that impacts your product quality, production timelines, and long-term profitability. While price and metal quality matter, they’re just two pieces of the puzzle.

Read on to learn the most important factors to consider when comparing metal suppliers.

Evaluate Lead Times

First, evaluate the lead times of each metal supplier. Longer than anticipated lead times can create a massive bottleneck in your business. They contribute to greater downtime and more production delays.

Consider these factors when comparing metal suppliers’ lead times:

- On-hand inventory: In most cases, the more on-hand inventory a metal supplier has, the more accurate their lead times and quicker their turnaround.

- Processing capabilities: If the supplier offers fabrication services, inquire about how long the process tends to take. A supplier with a large processing team will typically give more accurate lead times, while a supplier without a significant focus on processing may have inaccurate estimates or unexpected delays.

- Historical delivery times: To get a clear idea of a metal supplier’s lead time accuracy, look at their past performance. Get references from past and existing customers and see how they stack up.

Assess Inventory Depth and Variety

It’s also important to compare metal suppliers’ inventory depth and variety. The depth of a metal supplier’s on-hand inventory impacts more than just their lead times. Extensive on-hand inventory results in:

- Fewer supply-chain disruptions: In the manufacturing industry, events halfway across the world can cause supply-chain disruptions that significantly impact your business. The more inventory a supplier has, the less likely a global event is to have negative effects.

- Faster delivery: If you want your product quickly, on-hand inventory is key. It eliminates the waiting time for your supplier to receive product from their supplier, saving you weeks if not months.

- Potential cost savings: In some cases, purchasing from a supplier with on-hand inventory can result in cost savings. In addition to minimizing costs associated with time delays, your supplier may be willing to cut a deal on a bulk order that’s already in stock.

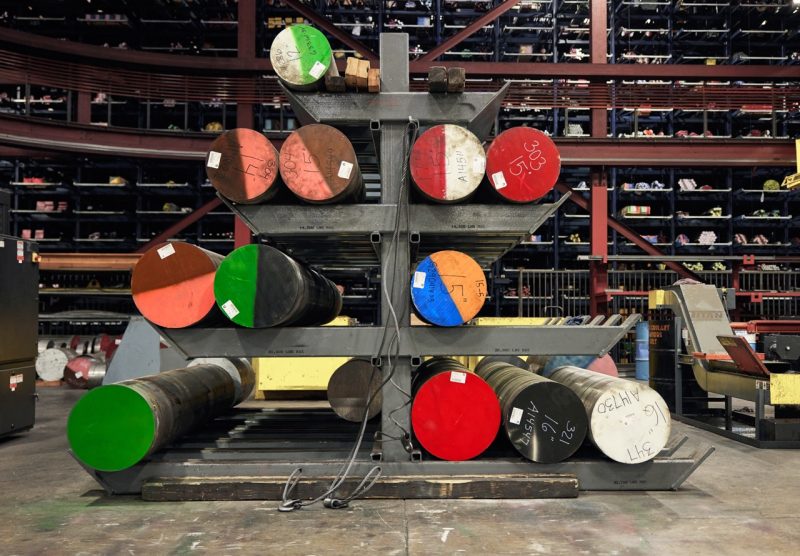

At Fry Steel, we’re committed to making your life easier by keeping an extensive inventory on hand. At any given time, we carry 140+ grades of steel, including stainless steel metals, superalloys, and more, in sizes up to 24” in diameter in 1/16” increments.

Consider Value-Add Services

When comparing metal suppliers, raw metal inventory and quality aren’t the only considerations. Buying from a supplier with in-house, value-added services can streamline your procurement process and save you money. Plus, when your materials pass through fewer hands, you reduce the possibility of handling errors and other issues.

When comparing alloy suppliers, stainless steel suppliers, or other metal suppliers, ask about any value-added services they offer like:

- Saw cutting

- Heat treating

- Grinding

- Forging

- Trepanning

- Custom packaging

Compare Quality Assurance Standards

Compare your metal suppliers’ quality assurance standards, as well as their practices surrounding traceability and documentation. Metal suppliers have both mandatory and voluntary quality assurance standards and certifications that govern traceability, documentation, metal quality, and more. For instance, suppliers are required to supply material safety data sheets along with products.

Of course, finding a supplier that complies with compulsory QA standards is essential, but the voluntary standards a supplier holds themself to may say even more about their reputability. These independently verified certifications hold suppliers to rigorous standards.

Depending on your industry, your prospective metal suppliers may adhere to the following ISO and AS certifications:

- ISO 9001 AS9120B: Quality management system standards for metal suppliers in the aviation, space, and defense industries.

- ISO 9001 AS9100D: Quality management system standards for organizations in the design, development, and production of aerospace products

- ISO 13485: Quality management system standards for organizations in the production of medical devices.

Verify Long-Term Stability

A strong, long-lasting partnership with your metal supplier is key to your success, so it’s important to find one with the financial strength to support long-term stability. While you may not be able to explicitly ask prospective suppliers about their finances, you can look to these factors to determine their viability:

- Longevity in the market: Generally, it’s better to work with a supplier who has been around for years than one that’s brand new to the game. They’ll have ironed out all their kinks, built strong relationships with their suppliers, and have greater financial stability.

- Diverse customer base: A diverse customer base prevents a supplier from becoming overly reliant on a single business or industry. It results in fewer fluctuations in cash flow for greater financial stability.

- Diverse product offering: Similarly, look for suppliers with a diverse product offering. A business that is restricted to solely an aluminium supplier or carbon steel supplier is much more at the mercy of the market than one with a wide range of products.

- Investment in facilities and technology: Well-maintained facilities and advanced technology can also suggest financial stability. They show a strong commitment to the longevity of the supplier’s business.

Check Coverage Range

For the best prices and fastest delivery time, choose a supplier with extensive geographical coverage for metal delivery services. Look for suppliers with multiple warehouses throughout the country. For example, Fry Steel has strategically located warehouses in both California, to cover the western region of the US, and Ohio, to cover the east. That means, no matter where you’re located, our warehouse is always just a few states away.

Gauge Customer Service Teams

It’s essential to partner with a metal supplier with responsive and knowledgeable sales and customer support teams. A knowledgeable sales rep doesn’t just order supplies for you, but partners with you to help you find the perfect product. Expert guidance can prevent you from spending thousands only to find you’ve bought the wrong supplies.

Responsive customer support is essential, too. While issues with your metal supplier are always a worst-case scenario, problems are inevitable. When they arise, it’s important to address them as quickly as possible to prevent a bottleneck in your production process.

Narrowing down your prospective metal supplier list takes time, but it’s a worthwhile task. Finding the right supplier for your business can save you money and time and contribute to a better final product.

For a supplier that exceeds these standards and more, partner with Fry Steel. We have more than 75 years of experience in the metal supply industry and the knowledge to match. Contact us today to get started.