When choosing metal for your project, it’s easy to get overly focused on a single metric, like its strength or weight, and assume that more is better. In reality, choosing a metal without considering the full picture can lead to performance concerns, higher costs, and problems down the line. It’s essential to understand how strength and weight interact to create parts that perform reliably without unnecessary complications.

Read on to learn all about metal strength vs weight, the differences between the two, and how to select the best metal for your application.

Understanding Metal Weight

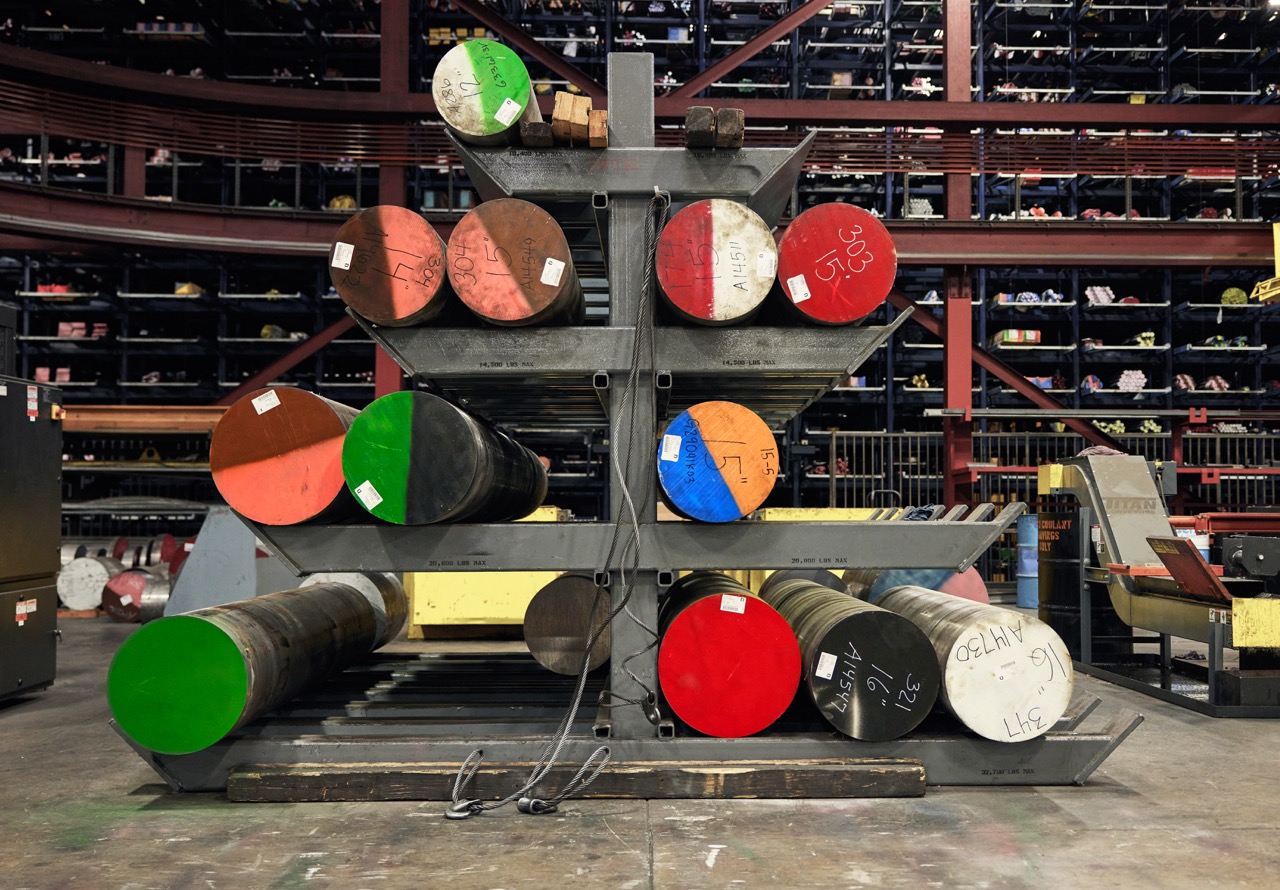

A metal’s weight is the metal’s density and volume. It’s a measurement of its mass, using the formula: Weight = Volume x Density. In precision metals, weight is measured per cubic foot (expressed as lb/ft³). Each type of metal or alloy has a specific weight. For instance, Grade 304 stainless steel weighs ~494 lb/ft³, whereas Grade 316 is slightly denser and weighs about ~498 lb/ft³.

A metal’s weight has a significant impact on the outcome of a final product and many of its implications. Lighter metals make for an easier-to-handle final product, lower shipping costs, and can even improve fuel efficiency when used to build aircrafts or vehicles. That said, they can often support less weight and provide less durability. Heavier metals, on the other hand, provide improved durability, but can increase production and shipping costs and make assembly more challenging.

Understanding Metal Strength

A metal’s strength is a measurement of its ability to withstand stress or bear weight without bending, breaking, or deforming. Strength is typically broken down into a few different measurements, including:

- Yield strength: The maximum amount of stress a metal can withstand before it permanently deforms.

- Tensile strength: The maximum pulling stress a metal can withstand before breaking.

- Compressive strength: The maximum squeezing stress a metal can withstand before failing.

- Impact strength: The maximum amount of energy a metal can withstand at once without shattering.

Why Strength Alone Can Be Misleading

A metal’s strength directly impacts the structural integrity, safety, and longevity of your final product. Strong metals are essential for safety and durability. That said, choosing a metal based on strength alone can lead to problems. It may lead to excessively heavy components, higher material costs, and more difficulty in machining, which can damage your final result.

How Different Metals Balance Weight and Strength

The weight and strength of a metal can be balanced using a number of different processes, including:

- Alloying: The strength of a metal can be dramatically increased without adding significant weight by alloying it with other elements. For instance, elements like chromium or molybdenum are added to stainless steel and other metals to improve their strength.

- Heat treating: Strength can also be improved by heat treating metals. This is the process of heating and cooling a metal multiple times and is commonly used for blades, tools, and other components that need to withstand a significant amount of stress.

- Cold working: Some metals are strengthened through a process known as cold working or work hardening. They may be rolled, bent, drawn, or go through other cold working processes.

High Strength-to-Weight Ratio Metals

A common measurement to look at when selecting metal is the material’s strength-to-weight ratio. A material with a high strength-to-weight ratio can withstand significant stress without adding significant weight. Common metals, alloys, and superalloys with high strength-to-weight ratio include:

- Aluminum alloys: These metals are lightweight while still providing moderate strength. They’re commonly used in industrial machinery and transportation.

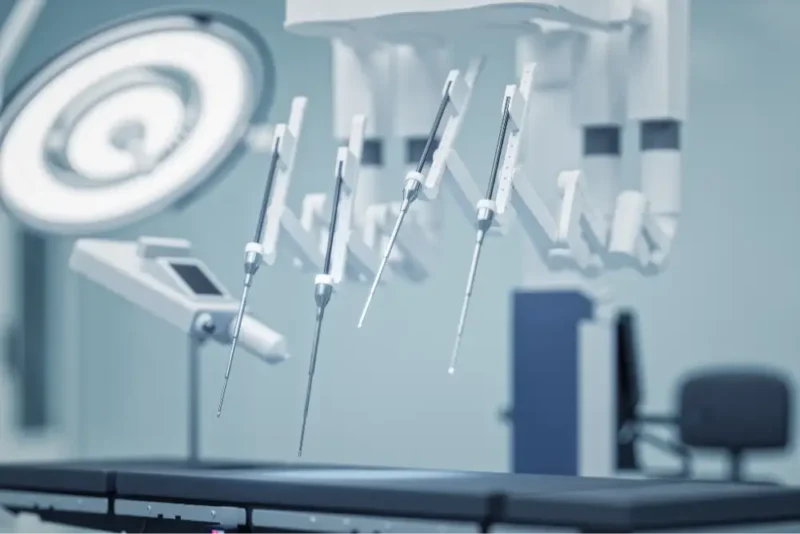

- Stainless steel: Stainless steel has considerable strength and medium weight. It’s commonly used in the construction, aerospace, and medical industries.

- Steel: While steel is very heavy, it’s also extremely strong. It’s often used in construction and machinery for load-bearing parts.

How to Choose the Right Metal

Finding the right metal for your purposes is a matter of striking the right balance between metal strength vs weight. Consider the following questions when deciding on a metal:

- What types of stress will impact the part?

- What are the considerations in terms of costs and manufacturing?

- Could a lighter material provide sufficient strength while improving efficiency?

Choose the Optimal Materials With Guidance From Fry Steel

There are a range of factors that go into choosing the best metal for your application, from strength and weight to machinability, corrosion resistance, and more. Rather than go at it alone, partner with a precision metals supplier with the experience to guide you to the best selection. At Fry Steel, we bring over 75 years’ experience in the precision metals industry, with expertise across industries like aerospace, defense, industrial, medical, and more. Find a Fry Steel representative in your region today.