Looking to improve cash flow, boost efficiency, and minimize waste? Your manufacturing business may benefit from a just-in-time metal supply strategy. This metal stocking program operates from the principle that you should only have the inventory on hand that you need. Its benefits are vast, but it requires a reliable and flexible metal supplier.

Read on to learn all about JIT metal supply, its benefits and challenges, and how to find the right partner for your supply needs.

What is JIT Metal Supply?

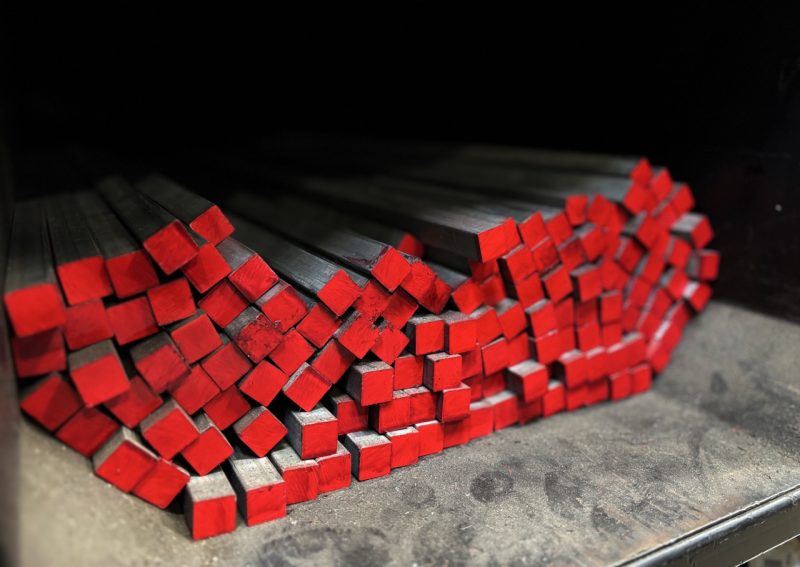

Just-in-Time (JIT) metal supply is a supply chain strategy that helps manufacturers keep their on-site inventory to a minimum. Rather than keeping bulk inventory on-hand at all times, manufacturers who use this metal stocking program order their inventory as the need arises. This results in smaller, more frequent metal deliveries with short turnaround times.

History of Just-in-Time Supply

Just-in-time manufacturing was popularized by Toyota in the early 1970s. It was developed to address seven types of waste identified in the manufacturing industry. These include the wastes of:

- Inventory: Wasting space and money by keeping too many raw materials and manufactured goods on hand. Instead, on-hand inventory should be limited to what is needed.

- Overproduction: Wasting time generating more than is needed. Instead, only necessary goods should be produced.

- Over-processing: Wasting time manufacturing to a higher standard than is valued by the customer. Goods should only be processed to the degree that the customer requires.

- Transportation: Wasting time and money transporting materials from one place to another. Manufacturing processes should be completed as close to one another as possible.

- Motion: Wasting energy on unnecessary movements. Instead, the manufacturing process should require as few movements as possible.

- Waiting: Wasting time on processes that aren’t in sync. Instead, processes should be as efficient and coordinated as possible.

- Defects: The waste of time and money spent on defective products. Instead, products should be generated in small batches as needed to limit the risk of defective products.

With JIT metal supply, manufacturing processes are slimmed down, waste is minimized, and efficiency skyrockets.

Why Manufacturers are Moving Towards JIT Models

Manufacturers are moving towards JIT metal supply in droves, and for good reason. This strategy offers a range of benefits, including:

- Lower storage costs: Storage is a primary cost in the manufacturing sector. With a JIT metal supply strategy, manufacturers keep less product on hand and can therefore lower their storage needs, driving significant savings.

- Less waste: Bulk metal stocking programs rely heavily on forecasting. Even with the most advanced forecasting strategies, waste is inevitable. Over time, the cost of wasted inventory adds up. JIT metal supply keeps unused product at a minimum.

- Greater flexibility: Just-in-time metal supply enables manufacturers to be more agile and keep up better with changing market demands. Manufacturers are no longer stuck manufacturing low-demand products simply because they already have the required inventory on hand.

- Better cash flow: This metal stocking program has the potential to greatly improve cash flow. Money is no longer tied up in extensive inventory and can instead be put toward growth.

Challenges of JIT Metal Stocking

While just-in-time metal supply poses many benefits, there are some challenges that manufacturers transitioning to this strategy need to be aware of:

- Forecasting requirements: There is still some forecasting involved in just-in-time supply. Manufacturers using this strategy have a limited buffer in the event of inaccurate forecasting.

- Delivery costs: Because JIT manufacturing results in smaller, more frequent deliveries, delivery costs can be higher than with bulk deliveries. Manufacturers need to carefully consider whether the savings of JIT supply will offset its higher costs.

- Supply chain disruptions: In order for JIT metal supply to function, the supply chain needs to run smoothly. Disruptions to the supply chain can result in long delays that draw production to a halt.

- Demand spikes: When an unpredictable spike in demand occurs, JIT manufacturers can have a harder time catching up to new levels.

- Supplier reliability: The reliability of suppliers for JIT manufacturers is of the utmost importance. An unreliable supplier can result in substantial disruptions to business.

What to Look for in a JIT Metal Supplier

Considering switching to just-in-time inventory management? Your partnership with your metal supplier is one of the most important facets of your business operations. Selecting the right JIT metal supplier can result in more efficient business operations and great cost savings, while the wrong supplier may leave you with greater delays and damaged customer relationships.

For the best possible outcome, look for these factors in your JIT metal supplier:

- Fast, reliable delivery: Speed is key when it comes to your metal supplier. Look for a supplier with short lead times and a consistent track record of fast metal delivery. If you can, find a supplier with a warehouse in your region.

- Strong quality control: There’s very little buffer room for quality issues with just-in-time metal supply. Your supplier should have strong quality control practices. Look for relevant QM certifications, like ISO 9001 or ISO 13485.

- Responsive support: Issues are inevitable. When they arise, it’s important that your supplier responds swiftly and strategically. Find a supplier with a communicative and readily available support team.

- Extensive inventory: In most cases, the fewer supplier relationships you need to manage, the better. Look for a supplier with a broad selection of stainless steel metals and more to suit your needs.

- Adaptability: Just like your manufacturing business needs to remain agile to keep up with changing market demands, so does your JIT metal supplier.

- Value-add services: Find a metal supplier that offers more than just raw materials. Value-add services like custom cutting can save you significant time, money, and hassle.

Fry Steel: Your JIT Metal Supplier

For a JIT metal supplier that meets all these requirements and more, choose Fry Steel. We bring decades of experience to a range of industries, from aerospace and defense to industrial, medical, and more. With two strategically-located warehouses in the West and Midwest, we offer fast metal delivery with the highest quality control standards possible. Contact us to learn more about our metal delivery services today.