Whether used in surgical tools, implants, prosthetics, or other medical devices, metals play an essential role in the medical device industry. Stainless steel and titanium are the most commonly used materials in medical devices, chosen for their corrosion resistance, biocompatibility, strength, and other properties.

Read on to learn all about materials used in medical devices, their specific applications, and why they’re so valuable.

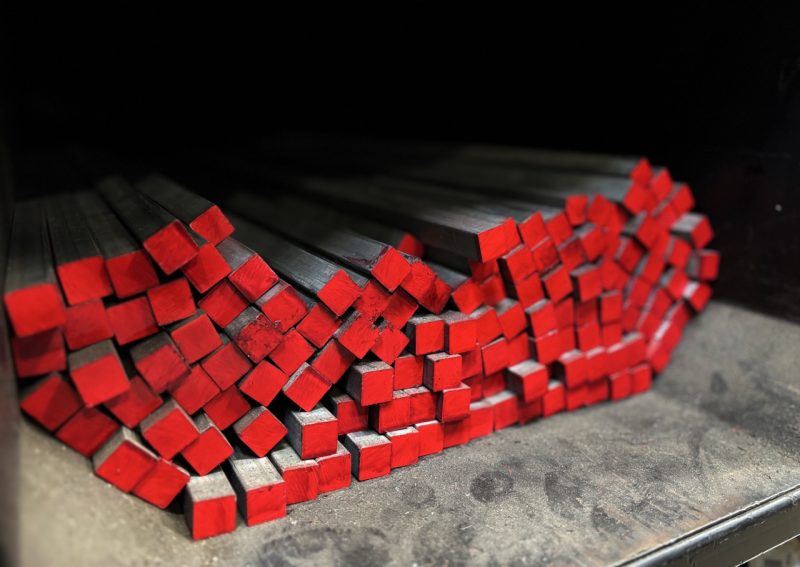

Stainless Steel

Among the most common metals for medical devices is stainless steel, namely 304 and 316L. This alloy is made of a combination of iron, chromium, nickel, and other components. Stainless steel for medical devices is widely used due to its:

- Corrosion resistance: Resisting rust and corrosion is essential for medical devices, which commonly come into contact with body fluids, sterilization fluids, and other liquids.

- Biocompatibility: These grades of stainless steel are highly biocompatible, meaning they won’t cause a reaction when it comes into contact with the human body.

- Non-porous surface: Porosity is another common concern when it comes to medical devices. Stainless steel’s non-porous surface means it can be easily sterilized.

- Ease of machining: Vital for manufacturers, stainless steel tends to be very easy to machine. Intricate tools can be easily constructed from this material.

Stainless steel for medical devices is most commonly used to construct components like:

- Surgical instruments: Stainless steel’s corrosion resistance and high strength make it a great choice for surgical instruments like forceps and retractors. It can also be honed to a very sharp edge in the manufacturing of scissors and scalpels.

- Guidewires: Because of its high biocompatibility, stainless steel is also commonly used to make thin, flexible guidewires.

- Orthopedic implants: Stainless steel is also a good material for orthopedic implants including pins, screws, and joint replacement, due to its excellent biocompatibility.

Specialty Alloys for Advanced Applications

While stainless steel is the most commonly used material in medical devices, it isn’t the only one. There are a number of different alloys with unique properties like superelasticity, high biocompatibility, and more that make them suitable to specific applications.

Although these materials aren’t as universally practical as stainless steel, they are just as essential. These specialty alloys include:

- Nickel-titanium alloy: This alloy has unique characteristics that make it particularly useful in medical devices like stents, catheters, and other implants. It’s both superelastic and has excellent shape memory, meaning it can be deformed for insertion into the body, then easily reformed into its original shape once inside.

- Cobalt-chromium alloy (CoCr): CoCr is very strong and highly corrosion-resistant, giving it long-lasting life. It’s commonly used in orthopedic implants like bone screws, plates, and more

- Niobium alloys: When alloyed with other materials, niobium can be highly machineable, enabling the construction of intricate devices.

- Platinum-iridium alloy: Platinum-iridium is highly biocompatible, extremely strong, and resistant to corrosion. Certain types are highly radiopaque, meaning they’re highly visible in extreme detail under x-ray and other types of imaging.

- Aluminum alloys: Aluminum is among the lightest-weight materials used in medical devices. This makes it a particularly good choice for surgical instruments, as it’s less likely to lead to fatigue during long procedures. It’s also used in non-load-bearing implants, though it’s not quite strong enough for those that need to bear a lot of weight.

Titanium

Both pure titanium and titanium alloys are FDA-approved materials for medical devices. When used, these materials provide benefits including exceptional strength-to-weight ratio, corrosion resistance, and osseointegration capabilities, meaning titanium devices can fuse with human bone and tissue.

Common applications of titanium metals for medical devices include:

- Implants: Titanium and titanium alloys are very common medical device implant materials due to their corrosion resistance, non-magnetism, and other key characteristics.

- Dental components: Due to their ability to osseointegrate, titanium materials are often used in dental components. It can fuse directly with the jawbone and surrounding oral tissue.

- Prosthetic limbs: Because titanium is very lightweight and strong, it makes a durable material for prosthetic limbs.

Polymers and Ceramics

Polymer and ceramic materials are used in medical devices, too, though they play a less central role than metals. They’re important for factors like insulation and wear resistance, and also provide a non-metallic alternative for FDA-approved materials for medical devices.

Polymers are commonly used in artificial blood vessels and sutures, whereas ceramics are often utilized in bone grafts and to coat metal implants.

Considerations When Selecting Materials for Medical Devices

Material type isn’t the only important consideration when selecting materials for your medical devices. Think about the following factors to guide your selection:

- Certifications: Metal suppliers who undergo voluntary certifications hold themselves to the highest standards available in the medical device industry. Seek suppliers with these rigorous standards for the best possible quality.

- Supplier knowledge: Your supplier should be your partner in the medical device industry. Look for a supplier with deep knowledge of and experience in materials for medical devices.

- Cost: It’s important to hit the right balance between cost-effective and reliable materials. It’s never a good idea to cut corners or sacrifice quality when it comes to medical device materials. People’s lives literally depend on it.

Source Your Materials for Medical Devices from Trusted Supplier Fry Steel

As important as the type of materials used in medical devices is the quality of those materials. Quality has a direct effect on device performance, procedure and patient safety, and other essential factors.

When selecting materials, it’s essential to work with a trusted supplier who understands the ins and outs of material standards for medical use, like Fry Steel. We work closely with the medical industry to support a range of needs. Fry Steel is ISO 9001:2015 and ISO 13485:2016 certified, and we supply materials that comply with ASTM F-899, the recognized standard for stainless steels used in surgical instruments and medical applications.

Ready to source materials you can trust? Connect with the sales rep in your region today.