In high-stress environments where performance and reliability are of the utmost importance, leading experts in a range of industries turn to superalloys. These metals combine standard alloys with materials like chromium, tungsten, and titanium to create a final product that’s strong, durable, and highly heat resistant.

Read on to learn all about superalloys, their key features, common types, and other essential information about these “super” materials.

What is a Superalloy?

A superalloy, also known as high-performance alloys or heat-resistant alloys, is a type of metal that’s designed to be extremely strong, resistant to very high temperatures, and have excellent surface stability. They’re made by combining common alloys like nickel and iron with other elements, like chromium, tungsten, and more, to create a single material with the strengths of many.

Key Features of Superalloys

Superalloys are named for their “super” performance, far exceeding other metals and alloys. Their key features include:

- Heat resistant: Superalloys can withstand extremely high temperatures, in some cases up to 2,200°F, without deforming. They resist creep, deformation under stress, and high temperatures very well. In environments with direct exposure to open flame and other sources of high heat, superalloys prevail.

- Strong surface stability: In addition to resisting creep, many superalloys form a protective oxide layer (like AlzO, or CrOs) that helps resist oxidation and corrosion. They excel in harsh marine environments and when exposed to highly corrosive chemicals.

- Resistant to thermal shock: Superalloys can undergo extreme changes in temperature without cracking or warping.

- Withstands repeated stress: These materials can easily withstand repeated stress from rotation and other repetitive movements without failure.

Types of Superalloys

Each type of superalloy is named for its base material, to which other materials are added to enhance its performance. The primary types of superalloys are:

- Nickel-based superalloys: Nickel-based superalloys, like Inconel, are among the most common in the aerospace industry due to their high creep resistance.

- Iron-based superalloys: Iron-based superalloys perform similarly to nickel-based, with the added benefit of being significantly less expensive to produce.

- Cobalt-based superalloys: Cobalt-based superalloys are newcomers to the superalloy market. These superalloys are typically made of between 50% and 60% cobalt, combined with 20% to 30% chromium and about 10% tungsten. The addition of chromium makes cobalt-based superalloys resistant to corrosion, even at high temperatures.

- Titanium-based superalloys: Superalloys made from titanium are known for their light weight and high strength, a hard-to-come-by combination. They also tend to be very resistant to corrosion, even when exposed to saltwater.

Superalloys vs Other Materials

Superalloys stand out from common alloys and materials in several different ways:

- Heat resistance: Superalloys can withstand temperatures that are several times higher than standard alloys.

- Performance: Superalloys take the performance of other materials to the next level. They’re incredibly strong in the face of heat, repetitive movements, and high-stress environments. They succeed where other materials would quickly fail.

- Cost: Superalloys are generally more costly than traditional alloys, but their exceptional performance and high reliability justify their higher price point.

How Superalloys are Used

Superalloys are used wherever performance is critical. Superalloys applications include:

- Aerospace industry: These materials are used in turbine blades, jet engines, and other high-stress, repetitive applications across both the commercial aerospace and space industries.

- Chemical industry: A common superalloy application, the chemical industry uses superalloys to build reactors, heat exchangers, and other parts that are regularly exposed to extremely high temperatures and corrosive materials.

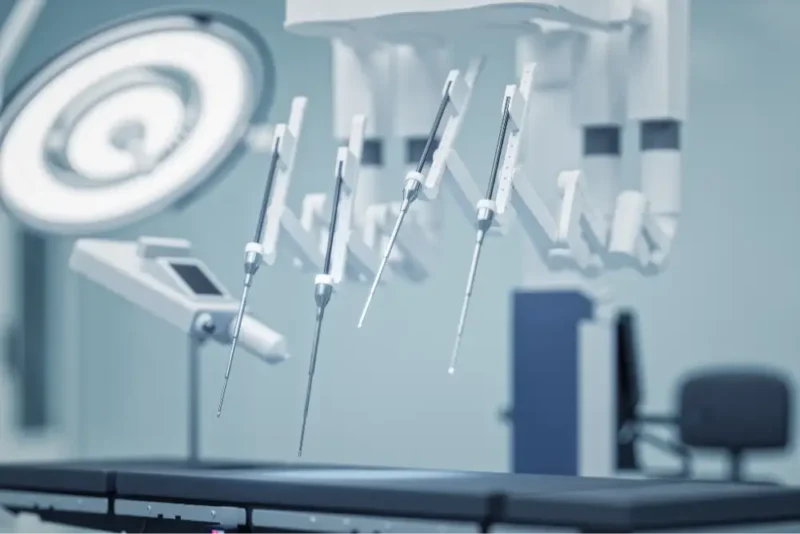

- Medical industry: Because of their surface stability and resistance to corrosion, superalloys are used to make implants, medical devices, and surgical tools.

- Marine industry: Their resistance to surface corrosion also makes superalloys excellent materials for marine turbines and other parts with constant exposure to harsh saltwater.

- Energy industry: Superalloy materials are commonly used in nuclear reactors, gas turbines, and other types of power generation.

Fry Steel: Your Trusted Superalloy Supplier

Fry Steel has been a trusted supplier of high-quality materials since 1948. Our specialty superalloys are designed for applications where reliability and performance are key. Fry Steel materials support critical industries including space, defense, industrial, and naval.

As an ISO 9001/AS9120/AS9100D certified company, we meet the global industry standard for quality and hold our suppliers to the same standards. Shop our range of leading superalloy products, in round bar, flat bar, hex bar, or square bar with custom sizes and cut-to-length services. A few examples of our superalloys include:

- 1 Hastelloy C-276

- 2 Waspaloy

- 3 Inconel 718 Cold Reduced Nickel Bar

When you need a material you can trust, turn to the suppliers trusted by leading names across the nation’s most essential industries. Shop superalloys from Fry Steel today.

Superalloy FAQs

What are the advantages of superalloys?

As compared to traditional materials, super alloys are more:

- Temperature resistant: Superalloys can withstand temperatures 2 to 3 times higher than standard alloys.

- Creep resistant: Superalloys resist degradation under prolonged stress far better than other materials.

- Corrosion resistant: Superalloys stand up better to corrosive materials and environments, like abrasive chemicals and harsh seawater.

What are the most common types of superalloys?

The most common brand names of superalloys include:

- 1 Hastelloy

- 2 Waspaloy

- 3 Monel

- 3 Inconel

What is the best superalloy?

Selecting the best superalloy depends on your superalloy application. Carefully consider how you’ll use your alloys and the specific characteristics you need. Nickel-based superalloys are known for their exceptional strength, making them an excellent choice for the aerospace industry. Iron-based superalloys are highly resistant to oxidation, a benefit for the automotive industry.

Can Fry Steel supply superalloys in custom sizes?

We happily provide cut-to-length services for all our superalloys. Talk to a Fry Steel rep about the specific requirements of your upcoming project.

1 Trademark Haynes

2 Trademark United Technology

3 Trademark Special Metals Corp.